Exploring 1-Bromo-4-Chlorobutane: A Commentary

Historical Development

Chemistry books from the middle of the twentieth century started talking more about halogen-substituted butanes. 1-Bromo-4-chlorobutane came out of that era, born from curiosity about the unique behaviors of halogenated organics. Laboratories across Europe and North America pushed to map out how specific halogen types would change a molecule’s properties and reactivity. Chemists discovered quickly that pairing bromine and chlorine on a butane backbone could open up a range of synthetic possibilities rarely matched by single-halogen siblings. As scientists began tailoring molecules for specialized applications from pharmaceuticals to materials science, this specific butane derivative started showing up more on lab shelves. The substance’s path from chemical curiosity to standard reagent reflects chemists’ ongoing need to fine-tune molecular tools for targeted work.

Product Overview

1-Bromo-4-chlorobutane draws the eye with its clear to pale yellow liquid appearance and a sharp, sweet odor typical of many alkyl halides. It sees routine use as an intermediate in the synthesis of longer-chain molecules. Industrial chemists ship it around the world for its track record in multiple-step organic syntheses. Its formula, C4H8BrCl, looks unassuming, but that single-chain backbone sets up the whole molecule for reactivity at the ends. Producers package it under a handful of names—4-chlorobutyl bromide, or even as part of custom reagent kits. Scientists working in fields as different as agrochemicals and surfactants circulate this chemical in their supply lists.

Physical & Chemical Properties

Pour this compound out at room temperature and you’ll notice its moderate viscosity, a boiling point clustered around 157-159°C, and density close to 1.42 g/cm³. The two halogens—bromine and chlorine—carry different weights in chemical reactions. Bromine atoms give up easily to nucleophilic attack, making this molecule handy for alkylation work. Chlorine, slightly less reactive, hangs back on the chain, sometimes left untouched when you want selective reactions. Solubility tilts heavily toward organics, barely moving in water. That insolubility cuts down accidental hydrolysis and makes recovery with organic solvents a simple affair.

Technical Specifications & Labeling

Bottles often come labeled with purity above 98%, dangerous goods indicators, and embossed hazard symbols for irritant and environmental danger. Safety sheets lay out threshold limits, flash point, and storage guidelines: cool, dry, with tightly sealed containers. Most reputable suppliers test for trace halides and other residuals, publishing typical impurity profiles. Regulatory teams include standardized GHS signal words and European REACH compliance notes on labels. Tracing origins or synthesis batches comes built-in with date codes and lot tracking, since any slip in chemical quality history sometimes causes reaction failures downstream.

Preparation Method

Years ago, labs prepared 1-bromo-4-chlorobutane by chlorinating 1,4-dibromobutane in the presence of sodium chloride or similar methods. Current practice involves the use of 4-chlorobutanol and phosphorus tribromide, which swaps a hydroxyl for a bromine. Yield tends to stay high, and purification usually gets handled by distillation or organic extraction. Some smaller outfits rely on phase-transfer catalysis, dropping reaction times and solvent needs. Modern work, though, cares just as much about reducing environmental footprint, so continuous efforts look to phase out toxic reagents and limit byproduct output.

Chemical Reactions & Modifications

Every chemist knows that 1-bromo-4-chlorobutane acts as a convenient source for butyl chains with built-in reactivity. The bromine end joins carbon skeletons through substitution, particularly in reactions with amines, thiols, or alkoxides. The spare chlorine waits for a second step, letting researchers add in other groups or carry the chain further. Cross-coupling reactions, such as those using palladium catalysis, employ this molecule as a starting point for more elaborate frameworks. Once in a while, people even run elimination reactions to install a double bond at the terminal position, creating possibilities for rings or rigid scaffolding.

Synonyms & Product Names

Catalogs list this compound under several aliases: 4-chlorobutyl bromide, 1-bromo-4-chlorobutane, or sometimes as its IUPAC name, 1-bromo-4-chlorobutane. For those working with multiple vendors, checking the CAS number—110-56-5—helps avoid mix-ups with other halogenated butanes. Different manufacturers may market under their own tradenames, but the underlying structure and properties remain identical.

Safety & Operational Standards

The presence of both bromine and chlorine means this chemical asks for careful handling. Inhalation of vapors or skin contact causes acute irritation and, in some people, more severe allergic reactions. Labs must equip themselves with fume hoods, gloves made from nitrile or neoprene, and splash-resistant goggles. Emergency eyewash stations and spill kits stand close by. Many organizations enforce double-signoff procedures on handling and dispose of any leftover stock via licensed chemical waste providers. Fire risks exist, owing to moderate flammability and release of corrosive gases under high heat. Proper ventilation and rigorous record-keeping form best defense against accidental exposure.

Application Area

Commercial operations and academic groups both make regular use of this compound in the assembly of specialty surfactants, biocides, and advanced materials. In recent years, pharmaceutical labs use 1-bromo-4-chlorobutane to install protected butyl groups on drug intermediates. Material science efforts put it to work on new polymer backbones or as a linking agent for functional nanomaterials. Companies producing antistatic coatings or special lubricants value its reactivity for anchoring side chains. Research into enzyme inhibitors or ion-channel blockers often reaches for this molecule as a building block to achieve tricky structural features impossible with simpler alkyl halides.

Research & Development

R&D labs focus hard on broadening the chemistry of 1-bromo-4-chlorobutane. Newer efforts target catalyst design for greater reaction efficiency, using less energy and waste. Studies track the selectivity of consecutive halide substitutions, trying to dial in exactly where and how to swap groups. Analytical chemists keep pushing limits for detecting trace contaminants, especially in pharmaceutical-grade intermediates. Green chemistry gets more attention each year, steering work toward solventless techniques or using renewable precursors for starting materials. Universities and corporate teams swap notes at conferences, aiming to stretch what these halogenated chains can do in functional molecular design.

Toxicity Research

Though not as notorious as some organohalogens, 1-bromo-4-chlorobutane still raises red flags in toxicology papers. Animal studies reveal acute toxicity at moderate exposure and possible chronic liver and nerve changes with long-term contact. Environmental fate studies stress that it bioaccumulates in certain soil and water systems, threatening aquatic life if not managed. To lower risks, many teams substitute out older reagents for less hazardous ones whenever possible, or design processes that limit worker and environmental exposure. Medical and safety literature repeatedly emphasizes robust handling protocols and swift response to accidental release.

Future Prospects

Industry trends show continued interest in halogenated building blocks, especially ones like 1-bromo-4-chlorobutane that offer selective reactivity. Growth in specialty chemicals, smart materials, and tailored pharmaceuticals keeps this molecule in play. At the same time, mounting sustainability expectations push for greener production and tighter lifecycle management. Scientists keep searching for cleaner synthetic steps and investigating biodegradation pathways. Regulatory landscapes shift, often requiring new toxicology and environmental impact data before approval for novel applications. As chemical manufacturing modernizes, expect this compound to feature in debates about balancing versatility, safety, and environmental responsibility.

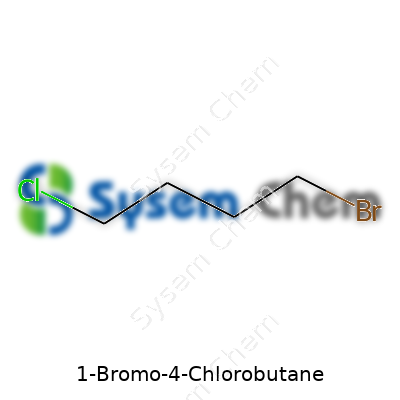

Breaking Down the Structure

It sounds simple: 1-Bromo-4-Chlorobutane. Chemists write its formula as C4H8BrCl. Each letter and number tells a story about the compound’s structure and its practical uses. The “1-Bromo” tells you there’s a bromine atom stuck to the first carbon atom, and “4-Chloro” means the fourth carbon holds a chlorine atom. Carbon and hydrogen atoms fill up the rest. That’s a straightforward molecular structure, but the real story comes from what this chemical can do outside of textbooks.

Why the Formula Matters

Understanding the formula means knowing the atoms, but it also shapes how this molecule behaves in a lab or a factory. C4H8BrCl looks like a mouthful, but it’s a common building block in organic chemistry. Students handle it during synthesis labs. Researchers rely on it to create new materials, medicines, and industrial products. The placement of bromine and chlorine affects what reactions can happen, which might sound trivial, but those reactions lead to useful products. That’s why the formula gets checked, double-checked, and sketched again by people who spend their days and nights making new molecules.

A Personal Connection

Early in my chemistry studies, working with halogenated butanes showed me the importance of asking not only “What’s the formula?” but also “What does this mean for safety, health, and impact?” I messed up once by misreading a similar formula, adding a bromine where there should have been a chlorine, and learned how even a small error can change everything—sometimes in a dangerous way. That kind of mistake in a larger scale lab would cause a chain reaction (no pun intended) of wasted time, lost money, and safety concerns. The formula, C4H8BrCl, may look simple, but it asks for respect and attention.

Risks and Responsible Use

Every chemical, especially one with bromine and chlorine, calls for care because of its toxicity and reactivity. People who handle it need solid training and clear safety protocols. Data from regulatory agencies show that mishandling halogenated chemicals leads to accidents in academic and industrial labs each year. Clear labeling, good ventilation, gloves, goggles—those aren’t just best practices, they’re non-negotiable standards that come from decades of hard lessons. Being careless with something like 1-Bromo-4-Chlorobutane puts people at risk and endangers the environment if it leaks or gets dumped.

Going Forward: Solutions and Safer Chemistry

Focusing on sustainable chemistry, some labs now push to replace harmful halogenated solvents and reagents with safer or greener alternatives. For cases where using 1-Bromo-4-Chlorobutane is essential, closed systems, monitored waste disposal, and ongoing education help reduce hazards. Sharing these safety stories—more than just reciting a formula—creates a culture of responsibility. Facts matter, but they only become valuable when people use that information wisely, not just in theory but on the benchtop, every day.

Why Chemists Reach for 1-Bromo-4-Chlorobutane

Most people probably never give much thought to compounds like 1-Bromo-4-Chlorobutane. For a lot of us working with chemicals, this substance comes up as a building block, not something you find in your kitchen cupboard or medicine cabinet. Whether you’re a synthetic chemist pushing the boundaries in pharmaceuticals, a materials scientist tinkering with polymers, or even a student in an organic chemistry class, this compound turns up when flexibility and reactivity matter.

Building New Compounds, Step by Step

1-Bromo-4-Chlorobutane has gained a reputation as a handy alkylating agent. In plain English, that means it works well for sticking pieces together in chemical reactions. Think of it as a connector, helping scientists add a four-carbon chain to other molecules. In pharmaceutical labs, that’s a big deal. Sometimes, tweaking a side chain on a potential drug molecule can flip the activity or safety of a compound. For anyone who’s spent long hours running NMR or TLC plates, finding a reliable reagent that reacts smoothly can make or break a project timeline.

A Role in Making Better Materials

On the materials side, people use 1-Bromo-4-Chlorobutane to modify or synthesize custom polymers. In the hunt for better plastics or new coatings, scientists often need specialty chemicals that impart specific traits — like flexibility, water resistance, or even electrical properties. This compound helps insert halogen atoms—bromine and chlorine—into a polymer chain, sometimes changing how the finished product handles under stress or how it resists environmental breakdown.

From Research to Real World: Agrochemicals and More

Search through patent databases and published papers, and you’ll see this compound pop up in the development of agrochemicals. Insecticides or fungicides sometimes call for special halogenated butanes as starting points. A friend who worked at an agrochemical startup once joked that half the job was figuring out how to stick the right chain on the right molecule to target the right pest. With 1-Bromo-4-Chlorobutane, chemists gain that modular choice, shaping molecules for the task at hand.

Safety Never Goes on the Back Burner

Any commentary on organohalides like this one needs to mention safety. Through experience, it’s clear that solvents and reagents like 1-Bromo-4-Chlorobutane shouldn’t be handled without proper ventilation, gloves, and a clear plan for disposal. Industry regulations, especially in the EU and United States, ask for full documentation and risk assessment. Safer alternatives keep popping up, but the demand for these versatile halogenated chains persists. Everyone in a chemistry lab needs solid training and access to up-to-date safety data sheets.

The Push for Greener Chemistry

Some universities and industry groups invest in green chemistry approaches, aiming to cut down on hazardous waste and accidental releases. Methods that minimize waste, recycle halogenated byproducts, or use milder conditions are gaining steam. Having spent years dealing directly with these compounds, I see how small procedural changes — switching to non-chlorinated solvents, recycling old reagents — add up over time. Each push for cleaner methods saves money and reduces risks long-term.

Looking Ahead

1-Bromo-4-Chlorobutane holds an important spot in the toolkits of chemists working across pharmaceuticals, polymers, and agrochemicals. Its reliability and effectiveness let scientists design, build, and tweak molecules to meet new challenges. Better safety guidelines, investment in greener processes, and discipline in handling set a path toward more responsible science. For those of us who have measured, weighed, and reacted with these chemicals, practical experience keeps teaching lessons that can’t be found in textbooks alone.

Understanding the Chemical’s Risks

1-Bromo-4-chlorobutane shows up in many labs and chemical industries. It’s a colorless liquid, but don’t let that fool you. This stuff causes trouble if you breathe it in, get it on your skin, or let it splash in your eyes. Bleach meets paint thinner — the smell alone hints at its potency. Slippery gloves and shifting goggles are no match for a substance that can cut through the normal latex barrier. Over the years, accidents keep popping up due to not taking this chemical seriously.

Personal Protective Equipment (PPE) Is Non-Negotiable

No one walks into a lab in sneakers and a t-shirt expecting to handle 1-Bromo-4-chlorobutane. I remember the first lesson from my mentor: always pull on thick nitrile gloves, snap on splash goggles, and wear a lab coat that closes at the wrists. Skip the open shoes and loose sleeves. If there’s any risk of a big spill or splash, I reach for a face shield on top of everything else. Gloves need to get checked for holes and replaced often, since this chemical eats through materials faster than you think.

Ventilation Cuts Down Fume Exposure

One whiff of 1-Bromo-4-chlorobutane and your throat starts to sting. Every time it poured into a flask, fumes started to fill the air, so I worked with it under a fume hood. These hoods make a noticeable difference, sweeping away gas and keeping hands steady. No need to suffer headaches, dizziness, or worse just from breathing in careless amounts. Good ventilation remains a top reason why fewer people end up with chemical burns or respiratory trouble in the lab.

Spill Response and Cleanup

I’ve seen more than one spill go sideways because someone thought a paper towel would cut it. Anytime a liquid like 1-Bromo-4-chlorobutane hits the bench or floor, grab a chemical absorbent pad and wear those gloves. Wipe from the outside toward the center to trap any spread. Everything gets sealed in a proper hazardous waste bag; leaving it in the open garbage invites a bigger mess. A safety shower and eye wash station must sit close, so there’s no sprinting down hallways during accidents.

Storage with an Eye on Compatibility

This chemical refuses to play nicely with strong bases or oxidizers. Store it in a cool, well-ventilated spot, away from direct sunlight and heat. Every bottle receives a clear label, and nothing sits above head-level. Experience taught me to keep containers tightly closed. Leaks from vapors will corrode nearby metal and send fumes across long distances, ruining a safe workspace in less than a day.

Training and Awareness Save Lives

Before anyone gets to work with this compound, real training matters. Reading the safety data sheet only gets you so far. Demonstrating the proper way to open bottles, transfer, and respond to an emergency takes time but saves trips to the emergency room. Weekly refresher drills and ongoing discussions about chemical safety kept me and my coworkers in one piece, even when new people joined the team.

Potential Solutions for Safer Labs

Switching to less toxic chemicals for certain reactions takes planning but often works in academic settings. Upgrading to gloves designed specifically for halogenated organics and investing in improved ventilation equipment help as well. These steps form part of a culture that never assumes experience alone can prevent mishaps. Chemical safety draws strength from habit, training, and the willingness to adapt as new data comes in.

Getting to know the basics

Start with a four-carbon chain. Add a bromine atom at one end and a chlorine atom at the other. That’s 1-Bromo-4-Chlorobutane. With the molecular formula C4H8BrCl, it’s a compound that shows up across organic labs. The halogens on each end give it a distinct character compared to many other straight-chain butanes.

How it looks and smells

Pouring it from the bottle, you’ll see a clear, colorless liquid. Don’t expect floral notes — like most small haloalkanes, it smells sharp and chemical, strong enough to leave an impression on your memory. Slip it between your fingers and you’ll notice it feels slick, less viscous than a syrup, running like a thin oil.

How heavy a molecule can feel

With the bromine sitting on one end and chlorine on the other, the molecular weight averages around 171 grams per mole. That’s heavier than most common hydrocarbons with the same boiling range, and it means it evaporates slower than plain butane or pentane. You can feel this weight once you’ve tried moving a flask of the stuff around in the lab.

Boiling and melting points tell a story

One thing always rings true — stick halogens on a molecule and you watch melting and boiling points climb. 1-Bromo-4-Chlorobutane boils near 163°C, so you can sometimes catch its vapors in warm labs if ventilation isn’t set right. Its melting point sits much lower, below -30°C. This means it pours easily straight out of cold storage, even in the dead of winter.

The way it mixes and reacts

Mix it with water and the two barely interact. Like most small alkyl halides, 1-Bromo-4-Chlorobutane is not water-soluble, but pour it into ether, acetone, or most organic solvents and it vanishes with a swirl. In my own work handling reactive intermediates, seeing a compound that dissolves so readily in these solvents gives a lot of options for different types of chemistry.

One major warning: just because it blends in easily with nonpolar solvents doesn’t mean it’s safe to forget about. It’s heavier than water, so it usually forms the bottom layer in a separatory funnel. Forget that, and you end up tossing your material or contaminating other products.

Chemical behavior sets it apart

The presence of two different halogens makes things interesting for design of syntheses. Nucleophilic substitution creeps to the top of the list; the bromine leaves faster than the chlorine, which sits tighter thanks to its slightly smaller size and stronger bond. I’ve seen folks take advantage of this in making specialty surfactants and as intermediates for pharmaceuticals and polymers. For any chemist, knowing the order in which atoms move on or off — who leaves first, who stays — helps avoid one-pot messes and wasted time.

Handling it day-to-day

Store it well-sealed, away from flames. Like many small haloalkanes, it can be a skin and respiratory irritant. Anyone working with it should put on gloves and eye protection, and make sure air’s moving through fume hoods. Regulators ask for this for a reason; one mistake can lead to nasty burns or lingering coughs.

The bigger picture and long-term impact

1-Bromo-4-Chlorobutane ends up as a toolkit molecule for industrial and research chemists. Its reactivity, immiscibility with water, and distinct halogen pattern allow for tailored syntheses of more complex molecules. Environmental regulations set out clear rules for disposal and handling, and these don’t just come from worries over personal safety; persistent halogenated compounds need careful management to avoid buildup in soils and groundwater.

This is a molecule that gets handled with respect, from weighing out a few grams for a reaction up to barrels moved at the plant scale. Making smart, informed decisions about its use helps keep people and environments safer, while opening doors for creative science.

Understanding What Makes 1-Bromo-4-Chlorobutane a Special Case

1-Bromo-4-chlorobutane brings both curiosity and caution into any lab or workplace. Used as an intermediate for organic synthesis, it’s colorless, has a distinct chemical odor, and doesn’t hide its presence. The stable halogen atoms make it practical for making other compounds but also mean it isn’t as forgiving as other lab solvents if spilled or mishandled.

Storing 1-Bromo-4-Chlorobutane Safely

Most of us who’ve handled volatile organics know that storage often gets overlooked in the rush to get things done. 1-Bromo-4-chlorobutane prefers cool, dry, and well-ventilated quarters, tucked away from sunlight and heat. Metal and halide containers rarely mix well; glass bottles with tightly sealed caps stand as the reliable choice. Labels aren’t decoration. They keep people from making dangerous mistakes, especially in labs with rotating staff or shared storage.

Shelf life shortens with careless storage. Moisture creeps in, and—if you’ve seen the result—sometimes builds up enough pressure to crack weaker containers. A spill in a crowded storage area doesn’t just stink up the room, but might also risk burns or toxic exposures. That fact makes secondary containment more than a box-ticking exercise. Plastic trays work well for catching leaks, and keeping incompatible chemicals apart—strong bases or oxidizers—gives peace of mind.

Personal Experience: What Happens Without Respect for Protocol

Years ago, I watched a co-worker rush and end up with leaking chloroalkane on the bench. Gloves melted, fumes sent half the room coughing, and we spent precious minutes trying to neutralize the mess. In that situation, ready access to spill kits, gloves, and goggles made all the difference. Small exposures from a lapse in safety gear can still cause skin and eye irritation. This isn’t hypothetical risk—too much of this stuff in the air will make you sick, and repeat incidents carry heavy consequences for health.

Disposal: Leaving No Trace for Tomorrow

Pouring 1-Bromo-4-chlorobutane down the drain or dumping it in regular trash crosses a legal and ethical line. Treated as hazardous waste, it lands in special containers labeled for halogenated organics. Government agencies across the globe—OSHA in the US or the Health and Safety Executive in the UK—hand out big fines for cutting corners here, but the real penalty comes from accidental contamination or worker injury.

Professional waste disposal contracts work for large labs, but in community college labs or small businesses, careful documentation and regular pickups might not always happen. Joining local or regional chemical disposal programs, often run by universities or hazardous waste providers, fills that gap. Staying up to date with regulations pays off—rules change, disposal techniques evolve, and nobody wants a legacy barrel of forgotten chemicals holding up future progress.

Practical Solutions: Building a Safer Work Culture

Handling chemicals like 1-bromo-4-chlorobutane pushes every worker to act responsibly, look after others, and support a safety-oriented culture. Training shouldn’t just tick boxes—role-playing spills or near-misses, keeping records, and reviewing storage setups every quarter turns rules into habits. Posting big, clear signs about storage, emergency numbers, and the right PPE keeps safety in the everyday routine, not as an afterthought.

Handling toxic organics calls for more than good intentions—it’s a combination of solid procedures, accountability, and the honesty to admit that mistakes do happen. Setting up for safe storage and respectful disposal shows respect for workers, the community, and the future.