1-Bromopropane: A Close Look at a Controversial Chemical

Historical Development

Back in the early days of industrial chemistry, compounds like 1-bromopropane didn’t get much attention. After all, cleaning agents and solvents came from a pretty short list: trichloroethylene, perchloroethylene, and a few others. Over time, regulatory pressure clamped down on those old standbys due to their hazardous profile, environmental baggage, and sometimes, their links to cancer. Companies started digging for substitutes. 1-Bromopropane, which folks in the lab sometimes call n-propyl bromide, found its chance to step in around the 1990s. The chemical’s history reflects changes in workplace safety, the push for “greener” alternatives, and a pattern seen all over the chemical world: fix one problem, discover another. From a modest background, 1-bromopropane became a staple degreaser, sold as a safer replacement—at least at first glance.

Product Overview

Chemical industries light up at anything that cleans better, evaporates fast, or replaces a bad actor restricted by new laws. 1-Bromopropane checks those boxes. It’s colorless, sharp-smelling, non-flammable, and tackles grease on electronics or metal with ease. Dry cleaners jumped on it when perchloroethylene fell out of favor. Aerospace assembly lines found it handy. Adhesive makers liked how it dissolved glues without sticking around as residue. Manufacturers stamped out millions of liters since the early 2000s, labeling drums for shipment all over the world, giving 1-bromopropane fresh relevance where classic solvents lost ground.

Physical & Chemical Properties

This compound comes as a liquid at room temperature, boiling right around 71°C, and freezing at -110°C, so it stays liquid under pretty much any usual working conditions. The smell is sharp and almost sweet, which gets up your nose fast in a closed room. It evaporates quickly, making spills less of a puddle problem but more of an inhalation risk. Once you know it’s denser than water (with a specific gravity of about 1.35), you realize it sinks in washers or sumps and doesn’t mix much with water, but it dissolves plenty of greases and resins. 1-Bromopropane stands up to many bases but falls apart with strong acids or light, making storage in steel drums essential—with a lid that keeps out moisture and sunlight.

Technical Specifications & Labeling

Industry uses a registry number—106-94-5—along with labels warning workers: flammable vapors above certain temps, causes irritation, and long-term exposure isn't safe. Most drum labels show at least 99% purity, with color often measured to show it hasn’t broken down. Delivery includes a material safety data sheet, handling protocols, and sometimes pictograms that make the dangers visually clear, even for workers who don’t read chemical catalogs for fun. Handling guidelines change as researchers learn more, but the message stays clear: keep the room aired out, wear gloves, use goggles, and store far from oxidizers, acids, and anything that sparks.

Preparation Method

Chemists make 1-bromopropane through a reaction between n-propanol and hydrobromic acid, or they use phosphorus tribromide in place of the acid. The setup feels old-school—straightforward substitution reactions. They mix the alcohol and acid, heat it up, and drive off water and the product, which they separate out and clean up by distillation. Every batch uses careful control to cut by-products like dibromopropanes or propene. The final purification step sets industrial-quality solvent apart from lab-grade samples.

Chemical Reactions & Modifications

With a bromine atom tucked onto a small hydrocarbon chain, 1-bromopropane acts as a decent alkylating agent, turning up in syntheses that build larger molecules by swapping out the bromide. Given enough heat or a catalytic push, it can knock its bromine off for nucleophiles looking to build custom chemicals. It gets used in the lab to tack propyl groups onto other compounds—pharmaceuticals, for example, and specialty polymers. Given the right set of reagents, you can make n-propylamine or swap the bromide for other halides, amines, or even thiols. It’s not just for cleaning; the molecule adapts to many uses behind the scenes.

Synonyms & Product Names

What people call a compound changes how it’s used and recognized. In chemical catalogs, you’ll see 1-bromopropane, n-propyl bromide, and sometimes just NPB. Sometimes it hides under trade names in cleaning or adhesive products. If you pick up a can of degreaser, the contents section could list nPB, 1-BP, or a dozen brand names. Different regions and companies write the name a bit differently, but the stuff inside remains the same clear, sharp-smelling liquid with a complex safety profile.

Safety & Operational Standards

Anyone who’s worked on an assembly line or in a solvent warehouse knows gloves and masks aren’t just suggested gear when handling 1-bromopropane—they’re the rule. The Occupational Safety and Health Administration (OSHA) didn’t regulate it until toxicology studies caught up, and now permissible exposure levels get tighter every few years. Direct skin contact burns, while vapor hits the lungs hard, with repeated exposure linked to neurological symptoms—headaches, dizziness, and worse. Air monitoring now comes standard in many workplaces using the solvent, backed up by ventilation systems, regular training, and sometimes, medical screenings. Regulatory agencies regularly update labeling requirements as understanding deepens about the risks.

Application Area

Machine shops and manufacturing lines started using 1-bromopropane to clean metal parts, prepare surfaces, or strip adhesives. Dry cleaning outfits turned to it as a replacement solvent when previous options faced bans or supply shortfalls. Electronics factories use it for circuit-board cleaning because it dries fast and leaves so little residue behind. Aerospace found a sweet spot for it in prepping composite materials. The same properties that make it valuable—low flash point, quick drying—also drive interest in research circles for stripping away experimental residues or prepping complex labware.

Research & Development

Research never sits still once users see health hazards or environmental persistence. Studies into 1-bromopropane’s breakdown rate in soil and groundwater discovered it sticks around much longer than expected. Universities and private labs now chase ways to degrade the compound more rapidly after use, or substitute it entirely with greener, non-halogenated solvents. Some groups explore bio-based replacements; others trial closed-system washers to capture every vapor. Improvements in personal protective gear and ventilation come as a direct response to field studies reporting adverse health effects among workers. The push for replacement or mitigation rides on new research every year, with journals filling up with alternative solvent ideas—few of which perform exactly like the compounds they’re meant to replace.

Toxicity Research

Real-world evidence on 1-bromopropane built slowly, with the first red flags raised by workers complaining of numbness, tremors, and memory struggles after months of daily contact. The National Toxicology Program and EPA funded rodent studies and eventually linked chronic inhalation to an elevated risk of cancer and reproductive harm. Blood samples from factory staff sometimes show breakdown products of 1-bromopropane long after leaving the job. The International Agency for Research on Cancer (IARC) gave it a “possibly carcinogenic” rating, enough for newer workplaces to steer clear or limit staff exposure to levels well below older guidelines. Researchers keep tracking subtle neurological and immune effects, as even brief contact over years might spark problems invisible in short-term animal tests.

Future Prospects

The future for 1-bromopropane hangs in a balance between its practical value and mounting evidence about its risks. My own time in industrial chemistry labs tells me industries rarely walk away from a tool that works perfectly, unless regulators make it non-negotiable or a game-changing alternative comes along. If upcoming research produces a safe, effective, reasonably priced cleaner, 1-bromopropane could start gathering dust like the solvents it replaced. Until then, industries try to minimize exposure, run closed-loop systems, and build awareness among workers. With stricter workplace limits rolling out in North America, Europe, and Asia, 1-bromopropane may gradually lose ground. Each decade’s lessons on worker safety and environmental fallout end up shaping industry habits, and 1-bromopropane stands as a clear example of how the search for substitutes sometimes leads right back to square one.

Solvent Workhorse on the Factory Floor

Factories across the world rely heavily on 1-bromopropane as a cleaning solvent. You’ll find workers using it to clean metal parts, spot-clean electronics, or prep surfaces before painting. Automotive shops use it to strip grease and gunk from engine pieces. Printed circuit boards wouldn’t stay pristine without a strong solvent, and 1-bromopropane steps up, pulling away residue without water. Its ability to dissolve oils and sticky industrial messes makes it a go-to choice, especially when fast evaporation matters. Many factories look for substitutes, but the performance of 1-bromopropane draws companies back—sometimes out of habit, often because finding an exact replacement isn’t easy.

Textile and Dry Cleaning

Dry cleaners saw an alternative in 1-bromopropane once stricter rules started squeezing out perchloroethylene. Smaller shops jumped on board, drawn by its potential to tackle stains and vanish without a trace when heat rolls in. Textiles absorb a fair amount of oil during processing, so wash lines benefit from the solvent power. Although it cleans well, the health and safety of workers raise concern. Not all shops have the kind of ventilation it takes to keep exposure in check. Responsible business owners weigh these risks every day.

Adhesive Sprays and Aerosol Products

The glue holding your office chair seat or the spray adhesive sticking foam to car interiors uses chemicals that need to dry fast and spread thin. 1-bromopropane finds its way into cans of adhesive spray—furniture makers and auto upholsterers know it by trade names, but the stuff inside often contains this solvent. It flows well, carries glue to hard-to-reach spaces, and leaves a clean bond after flashing off. The lightweight nature of spray adhesives keeps jobs moving, but workers using these products should always be mindful of what’s in the air around them. Masks and open doors make a difference.

Electronics and Precision Cleaning

Electronics manufacturing has unique cleaning needs. 1-bromopropane can flush away solder flux and keep sensitive components from corroding before final assembly. Since water and electronics don’t mix, a solvent like this keeps circuit boards clean, preventing failures that leave customers frustrated. I’ve seen cleaning stations in electronics plants rely on fast-drying solvents, especially before packaging and quality control. Engineers look for a balance between aggressive cleaning and leaving no trace, driving ongoing debates about safety and alternative choices.

Health and Environmental Conversation

The U.S. Environmental Protection Agency (EPA) and OSHA both keep a close eye on 1-bromopropane. There’s evidence it’s toxic to nerves and may cause cancer after long-term exposure. I’ve read stories of workers developing symptoms after years in closed rooms where the chemical filled the air. States and companies consider switching to less hazardous solvents, but many replacements fall short in real-world cleaning tests. Solutions start with better ventilation, personal protective equipment, and clear rules for chemical handling. Some large manufacturers now invest in safer technologies, training programs, and air monitoring to cut risks. Each step toward safety means fewer health scares and a more responsible industry.

Practical Shifts and Safer Choices

Many in the cleaning and manufacturing business wonder where to go from here. Green chemistry offers some hope with water-based systems or safer organic alternatives, but these changes take investment and education. Workers deserve to know exactly what they’re handling and how to protect themselves. As more people learn about the risks, the demand for safer solvents rises. Businesses that step up find loyal customers and a stronger workforce, proving chemical safety pays off in ways that numbers alone can’t measure.

Looking Closer at Daily Exposure

Walking through car shops or furniture factories, you’ll probably smell something sharp and chemical—there’s a good chance that’s 1-bromopropane. Companies often use this solvent to glue foam, clean electronic parts, or degrease metals. Many workers have handled or inhaled this chemical before anyone paid attention to the health problems it caused. Over the years, mistakes and underestimations have piled up, especially when production lines depend on old habits and cost-saving shortcuts.

Learning From Real Harm

Stories of workers developing headaches, dizziness, trouble walking or even nerve damage often go unheard outside workplace safety meetings. Early research saw it as a safer alternative to ozone-eating chemicals. Reality turned out different. When the Centers for Disease Control and Prevention (CDC) followed up, they connected cases of numb fingers, poor balance, and memory lapses with 1-bromopropane exposure. Chronic contact wasn’t just unpleasant; it proved harmful. The National Institute for Occupational Safety and Health (NIOSH) called it a potential occupational carcinogen. In 2019, California labeled it as cancer-causing under Proposition 65, and more states started asking serious questions.

How Exposure Happens

Factories and repair shops aren’t always sealed cocoons. 1-bromopropane evaporates into the air, sticking to skin, sneaking into lungs when ventilation fails or masks don’t fit. Managers sometimes rely on outdated ventilation or cheap personal protection. Years ago, I watched coworkers skip gloves because “it’s just a little bit.” That “little bit” builds up. People felt fine for weeks, then sharp tingling or dizzy spells started. Science shows a link between breathing in high concentrations and getting sick, but problems can start at much lower levels—just by getting it on your hands and clothes all the time.

Research Points to Bigger Risks

Animal and human studies offer a clear pattern: the toxic effects go beyond the nervous system. Work published in Environmental Health Perspectives shows that long-term exposure increases risks for reproductive problems (like infertility), liver damage, and lung irritation. The World Health Organization’s International Agency for Research on Cancer (IARC) flagged 1-bromopropane as possibly carcinogenic to people. That’s not some distant threat; workers complain about symptoms that disrupt daily life, years after the job ended. Anyone who’s tried holding down a job while dealing with brain fog or numb feet knows the cost isn’t just physical—it becomes financial and emotional too.

Doing Better: Practical Solutions

Companies can swap out 1-bromopropane for safer alternatives in most cleaning and glue applications, though that takes investment and a willingness to break routines. Simple steps matter: better exhaust fans, basic glove training, and honest air monitoring all help. Regulators have caught on—OSHA points out permissible exposure limits and details specific handling procedures. Yet many small shops run on thin margins and little oversight. Incentives for safer products, public safety campaigns in multiple languages, and clear reporting systems for symptoms would reach more people. Health care providers should ask about chemical exposure when workers report unexplained neurological symptoms.

Workplace Advocacy Needs Real Voices

Keeping workers safe starts with telling honest stories, not hiding sick workers in the back. Union reps, safety committees, and industry leaders must make noise, share facts, and push for practical policies before the damage is done. Personal experience, epidemiological data, and regulatory action all point in the same direction—nobody should end up disabled from a job that could have been safer with common-sense precautions and smarter choices.

The Real Risks in the Workplace

Working with 1-Bromopropane (1-BP) feels just like handling other volatile solvents—until you learn what exposure does. Over the years, stories from co-workers and safety meetings have driven home the message: this isn’t just another chemical. People who’ve handled it without proper protection have ended up dealing with dizziness, headaches, or trouble with memory. Folks have shared how a single busy cleanup job left them lightheaded for the rest of the week. I’ve seen seasoned technicians remind newcomers that 1-BP isn’t just an irritant, it’s a potential neurotoxin.

Ventilation: The Foundation of Protection

It’s tempting to open the container and get to work, especially on a rushed morning. The thing is, vapors from 1-Bromopropane creep into the breathing zone before you smell them. I always insist on mechanical ventilation, not just a cracked window. Proper fume hoods or exhaust fans create a constant air flow, cutting down on the invisible build-up of toxic vapor. I remember a lab that swapped an old hood for a high-powered exhaust—respiratory complaints dropped overnight.

Personal Protective Equipment

The right gloves matter more than style. Nitrile or thicker chemical-resistant gloves actually block 1-BP, unlike basic latex. Goggles, not just safety glasses, keep the liquid from splashing into eyes. It’s clear why: colleagues who ignored gloves for a minute spent days with irritated skin. Even everyday clothes don’t cut it; lab coats or dedicated chemical aprons have saved many shirts—and probably some skin—from damage.

Respecting Storage and Handling

One time, I watched someone leave an open container on the benchtop. Within an hour, the sharp odor filled the entire lab. This chemical escapes into the air faster than most expect, so sealed containers are a must. Fire isn’t a far-fetched worry, either. 1-Bromopropane fuels flames and can ignite under the right conditions. Storing it away from heat spots and using only as much as needed keeps surprises down to a minimum.

Emergency Preparedness Matters

It’s easy to skip reading the safety data sheet, but anyone handling this solvent owes it to themselves to know the steps for spills, fires, or accidental splashes. Quick action is what keeps an accident from turning serious. Spills should get covered with absorbent and picked up fast—no dragging feet. Showers and eyewash stations should always be within ten seconds of reach. I’ve seen one colleague react fast to a splash and avoid a bigger problem, just because the safety gear wasn’t buried in a cupboard.

Ongoing Safety Training

Nobody gets it perfect every time, especially as regulations change and new findings come out. Regular refresher courses keep details in mind—not to fill an hour, but because short reminders can prevent months of trouble. I’ve learned that simply gathering once a year to talk through real incidents, not just tick boxes, makes folks more careful the next day.

Better Solutions Going Forward

Technology and research keep opening up less-harmful alternatives, but many sectors still rely on 1-Bromopropane. Until safer substitutes become the norm, strong workplace programs, routine air monitoring, and a culture that values health over speed make a real difference. Personal stories, not just statistics, stick with a team—and sometimes, that’s enough to keep the daily grind a lot safer for everyone around.

The Deal with 1-Bromopropane

1-Bromopropane, often called n-propyl bromide, shows up in plenty of workplaces. Dry cleaners and factories like this solvent, but folks handling it should remember: it’s not exactly gentle. Safety facts don’t need sugarcoating. Scientists link long-term exposure to nerve damage, and some studies warn about cancer risk. In my early days working in an auto shop, nothing drove home chemical safety more than watching a co-worker get a nasty headache from ignoring proper storage for solvents. The lesson: treat these chemicals with respect, or pay the price.

How Proper Storage Looks

Locking down storage starts simple. Solid metal drums or tightly sealed containers work best. Leaving these sorts of chemicals in thin plastic doesn’t cut it. Leaks spoil more than just the day—vapors from 1-bromopropane can mess with lungs and leave a building smelling for a week. Containers need strong labels, with warnings about fire, toxins, and the need for good ventilation. I’ve seen workers, busy with five projects, grab a jug only to realize too late they’re breathing something toxic. A clear label makes a difference.

Days get hot in summer, and sun-warmed storage brings risks. Cool, shady spaces reduce breakdown and keep containers from swelling or cracking. Fumes sneak up, so locked cabinets with a vent make handling safer. Storing near acids, open flames, or oxidizers? That just cranks up danger. Keep this stuff far away from anything that sparks or reacts.

Disposal: Don’t Take Shortcuts

Nobody wins if someone pours 1-bromopropane down the drain. That’s just moving the problem around. It doesn’t take long for sewer and river systems to pick up traces, harming fish and even making water tough to treat. City regulations usually say not to pitch this stuff in the regular trash, either. Hazardous waste collection points handle 1-bromopropane much more safely. I tried cutting corners in college, tossing leftover lab solvents in a dumpster, and got a strong talking-to from my teacher—never did it again.

Some companies contract out disposal, and this avoids both legal troubles and environmental headaches. The EPA stays strict on this; regular checks make sure businesses dispose of solvents the right way. Flushing 1-bromopropane into landfills or storm drains can bring big fines. Good recordkeeping also helps. Jot down when and how much gets disposed, so any questions from health inspectors don’t catch your workplace off guard.

Better Solutions and Everyday Habits

Solvents like 1-bromopropane will stick around, so education plays a big part. Teaching workers about hazard signs, air monitoring, proper gloves, and eyewear cuts down on emergencies. Sharing real stories of near-misses or mistakes can motivate teams to handle chemicals with care. Some companies explore alternative substances with a better health record. Substitutes reduce headaches for workers and keep the neighborhood safer.

Tools for spill clean-up should sit nearby. Absorbent pads, sealable waste jars, and spill kits belong on every shelf. If a spill comes, acting fast—using gloves, working upwind, and alerting co-workers—keeps trouble from spreading. Learning from others, checking the latest EPA rules, and making safety an everyday routine help turn a risky job into just another shift done right.

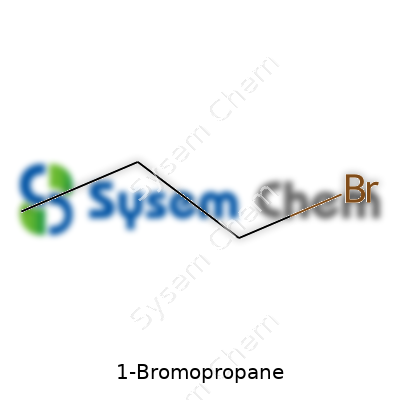

The Chemical Formula of 1-Bromopropane

1-Bromopropane goes by the formula C3H7Br. In its structure, three carbon atoms link together, and a single bromine atom attaches to one end of that chain. This arrangement turns it into a clear, colorless liquid. The molecular structure shapes the way the chemical interacts with other substances and how people use it for industrial work.

Key Properties Shaping its Use

The boiling point of 1-bromopropane hits around 71°C, not much higher than water. This low boiling point means it tends to evaporate easily at room temperature, so anyone handling it needs good ventilation and proper equipment. The chemical’s density sits at about 1.35 g/cm³, making it heavier than water. If spilled, it sinks rather than floats, creating real cleanup challenges.

It's not flammable as gasoline, but it catches fire if exposed to enough heat or an open flame. Once ignited, the chemical releases toxic gases, including hydrogen bromide. I've seen shop managers take extra caution around storage for this reason—sturdy metal shelves, clear labeling, and always keeping extinguishers nearby.

Applications and the Growing Health Discussion

In the working world, 1-bromopropane turns up everywhere from dry cleaning factories to electronics plants. As a solvent, it removes grease, oil, and adhesive residues with fewer harsh odors than older chlorinated solvents. Companies swap to 1-bromopropane because traditional options like trichloroethylene faced tighter restrictions for being carcinogenic. As a result, cleaning crews often favor this newer solvent, at least at first.

Problems cropped up not long after its arrival. Studies published by the National Institute for Occupational Safety and Health (NIOSH) found links between repeated exposure and nervous system symptoms—tingling in the hands, loss of coordination, headaches. A 2013 study in the American Journal of Industrial Medicine described workers developing symptoms after months using 1-bromopropane, often in poorly ventilated rooms. Absorption comes mostly from dust or vapor, especially in summer heat.

Long-term environmental concerns keep gaining attention. 1-bromopropane doesn't linger in the environment quite as long as some older halogenated solvents, yet the runoff can reach groundwater or seep into soil. Regulatory agencies like the EPA have flagged the compound for new risk assessments. Some countries already set exposure limits well below 5 ppm for workplaces.

Pushing for Safer Alternatives

More businesses now rethink their cleaning solutions, weighing human safety over sheer cleaning power. Alternatives based on water or hydrocarbons exist, though they can't always handle stubborn greases as easily. Managers and teams have learned that accurate ventilation, regular air testing, and training on handling spills all make a big difference—even before a major incident happens.

Every new chemical in an industrial setting brings its own mix of promise and peril. It takes time to see the full picture. Listening to workers, reading academic research, and choosing responsible chemical suppliers form the backbone of safe operations. Proper labeling, airtight containers, and routine health monitoring should be part of every protocol, with no shortcuts just to save money or time.