1-Chlorodecane: An Unvarnished Look at a Specialty Chemical

Historical Development

The history of 1-chlorodecane stretches back to the rise of synthetic organic chemistry, long before digital catalogs made chemical procurement simple. Chemists sought ways to manipulate alkanes, and halogenation unlocked new patterns of reactivity. Through generations, the need for alkyl chlorides with precise chain lengths grew steadily, driven by everything from industrial lubricants to chemical synthesis. Early labs first produced 1-chlorodecane in modest yields, usually through challenging, messy reactions involving gaseous chlorine and decane hydrocarbons. With refinement and industry interest, the process became more dependable. Picture vats of decane in postwar factories, with engineers closely monitoring the balance between yield and purity, careful not to overshoot the delicate chlorination step. Engineers learned to watch out for over-chlorination, which led to hard-to-remove byproducts. Today, modern chemical plants use streamlined processes and high-purity feedstocks, built on the lessons of earlier trial-and-error methods.

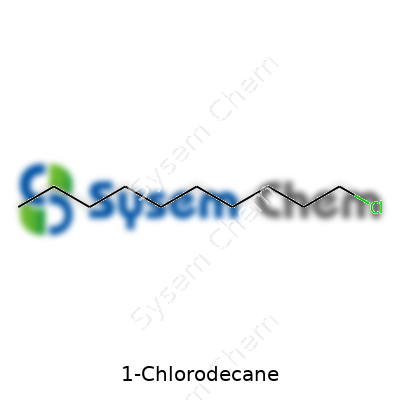

Product Overview

1-Chlorodecane is no household name, but inside the specialty chemicals sector, it earns respect. The molecule delivers a blend of attributes you won’t find just anywhere: a stable ten-carbon backbone capped with a reactive chlorine atom. Manufacturers use it to build longer-chain surfactants, lubricants, and intermediates. Researchers keep small bottles of it on hand for laboratory explorations, synthesizing compounds that need just the right mix of hydrophobic and reactive traits. Suppliers focus on delivering unadulterated 1-chlorodecane, free from shorter- or longer-chain analogs that could throw off a reaction’s outcome. This single-purpose focus means small differences in purity carry real consequences for downstream chemistries.

Physical & Chemical Properties

In a clear glass vial, 1-chlorodecane stands as a colorless, oily liquid. Its boiling point sits around 216°C, placing it among the medium-chain haloalkanes. With a density of about 0.85 g/cm³, it floats comfortably between water and heavier organic liquids. This compound won’t dissolve in water—its long alkyl chain refuses to mingle—but it mixes smoothly with most nonpolar organic solvents. A sharp, faintly sweet odor tips off its presence. Chemically, it resists slow degradation, but the carbon-chlorine bond offers an anchor point for further transformations, making it attractive for both industry and lab work. Its flash point (over 95°C) means hazards rise when handling quantities in open vessels near heat, so practical work demands attention and good habits.

Technical Specifications & Labeling

Bottles and drums come clearly labeled with the chemical formula, C10H21Cl, along with CAS registry number 112-85-6. Reputable suppliers spell out purity (97% or greater by GC analysis), water content, and any stabilizers present. Labels display UN numbers and standardized hazard pictograms as mandated by GHS guidelines. Details like batch number and manufacturing date remain crucial for traceability, especially since organic chlorides can degrade under light and air. Most labs keep drips and leaks at bay with thick plastic liners, and they stipulate that users check labels before decanting, as trivial errors cause real harm in multistep syntheses. This attention to labeling matters more than folks outside the lab might guess, since small missteps compound into costly batch rejections or, worse, hazardous exposures.

Preparation Method

Manufacturing 1-chlorodecane relies on free-radical chlorination, typically using decane and gaseous chlorine under carefully metered light or heat. In industrial settings, producers fine-tune the reaction with radical initiators and strict reactor conditions. Older methods, such as using phosphorus trichloride and decanol, faded because of hazardous byproducts and poor selectivity. Workers ensure proper ventilation since the process releases hydrochloric acid fumes, and temperatures get monitored so secondary reactions don’t spiral out of control. Once the reaction stops, the product mixture undergoes fractionation—usually vacuum distillation—since similar chain-length chlorides and unreacted decane lurk in the mix. Every liter meant for sale passes through quality checks for residual impurities, odor, and halide content. Controlled environments and skilled operators mean the difference between a clean, sellable batch and one that spends extra hours in cleanup.

Chemical Reactions & Modifications

As an alkyl halide, 1-chlorodecane excels at driving nucleophilic substitution reactions. In hands-on research, it serves as a starting point for synthesizing ethers, alkylated aromatics, or quaternary ammonium salts. Chemists may swap out the chlorine atom for other nucleophiles—like alcohols or amines—building tailored molecules stepwise. In more advanced applications, the chlorodecane backbone can serve in cross-coupling reactions, joining new fragments to the chain’s end. Its long nonpolar chain makes it valuable for creating surfactants, where it can anchor a polar head group on an otherwise oily base. This single carbon-chlorine bond, taken for granted at first glance, opens doors for both expanding and modifying molecular structures, giving scientists tools to tune chemical properties with high precision.

Synonyms & Product Names

Beyond the basic “1-chlorodecane,” suppliers use names such as decyl chloride, decane monochloride, and Chlorodecane-1. Some catalogs stick to English nomenclature, while others prefer German or French terms like “1-chlorodécane.” With each name, the underlying chemical stays the same, yet a search in an international registry might turn up subtle spelling changes. In safety programs, clarity about synonyms helps prevent confusion, especially when handling imports or cross-referencing materials safety data sheets from different jurisdictions.

Safety & Operational Standards

Working with 1-chlorodecane takes training and respect for both chronic and acute hazards. It can irritate skin and mucous membranes, so handling calls for gloves, eye protection, and fume hoods. Inhaling vapors or letting it contact unprotected skin causes lasting discomfort. Regulatory authorities classify 1-chlorodecane as hazardous, with explicit signaling on all packaging. Facilities store it in cool, shaded, and ventilated spaces, away from oxidizers or open flames. Cleanup routines involve dedicated spill kits and solvents like mineral spirits. Companies emphasize worker education about the risks, through signage and in-person safety briefings. Near misses and small leaks warrant incident reports, since even minor exposures—over time—cause cumulative harm. Training also covers environmental release controls; spills run straight into sand or absorbent pads, never drains, to prevent groundwater contamination. Waste bottles never go in common garbage—only designated hazardous collection streams.

Application Area

Though it never wins headlines, 1-chlorodecane underpins more technologies than most users realize. At the heart of its utility lies the combination of oil-loving chain and reactive site. Paints, coatings, and specialty lubricants often rely on derivatives built from its backbone. Chemical companies treat it as a raw material for surfactant production, tailoring detergents with predictable wetting and spreading profiles. Some pharmaceutical syntheses lean on it as an intermediate, using its chain for modifying bioactive compounds. Material scientists appreciate its role in developing anti-static agents and specialty polymers. Petroleum refineries include it in formulations that modify viscosity or impact cold flow behavior. From bearing grease additives to water-repellent coatings, the reach of this single compound runs wide—and reveals how often mundane molecules quietly power big industries.

Research & Development

Scientists and technologists keep exploring new ways to stretch 1-chlorodecane’s limits. Some pursue greener synthesis routes, looking to cut out hazardous reagents or unnecessary emissions. Others work toward catalysis, searching for metal- or enzyme-based processes that boost selectivity and lower waste. Academic labs probe the reactivity of its carbon-chlorine bond under different conditions, seeking insights for designing next-generation surfactants and polymers. Studies also circle around the environmental fate of mid-chain alkyl chlorides, tracking how they break down and where residues linger. Industry and academia sometimes team up, pooling resources to find less toxic substitutes for related compounds. Researchers look for ways to use less energy in large-scale manufacturing, trimming costs and footprints for the future.

Toxicity Research

1-Chlorodecane earns a spot on controlled lists because of its toxic profile. Laboratory studies show it can cause skin and eye irritation. Repeated exposures, whether by inhalation or skin contact, raise risks for organ damage—including effects on liver and kidney in animal studies. The compound’s fat-loving chain helps it slip into biological membranes, making it harder to clear from tissue once absorbed. Environmental scientists investigate its breakdown in soils and groundwater, since chronic release threatens wildlife health. Regulations specify exposure thresholds, mandating air monitoring and medical surveillance in regular-use facilities. Researchers continue to study possible links to developmental problems and carcinogenic potential; evidence stays mixed, but the need for vigilance stands clear. For workers, practicing restraint and prioritizing engineering controls keeps incidents rare, but not impossible.

Future Prospects

Looking ahead, 1-chlorodecane will likely stick around where specialty requirements demand its unique features. Green chemistry advocates press for better process efficiency—fewer emissions, solvent replacement, and recyclable catalysts all stand at the top of the wish list. Chemists push for designer molecules, hoping to unlock new uses for customized chlorinated chains. With the rise of stricter environmental and workplace regulations, the industry faces calls to shrink waste and watch for substitutes where feasible. Some startups investigate biosynthetic alternatives or bioremediation methods to mop up legacy contamination. While the demand for mid-chain alkyl chlorides dips and surges with economic cycles, end-users still count on reliable, pure product for advanced syntheses and formulations. Research on toxicity and environmental fate will shape production standards and drive innovation, keeping the balance between progress and responsibility in sharp focus.

What is 1-Chlorodecane?

1-Chlorodecane looks like another long chemical name pulled from a textbook, but, in truth, it’s a straightforward organic compound. Chemists often treat it as a building block, with a makeup that’s clear and a bit oily to the touch. Folks who work in labs refer to it by its formula, C10H21Cl, just to make things quick. This compound falls into the chlorinated alkanes group, which matters once it’s time to dig into how businesses and researchers put it to work.

Industrial Applications: Getting Practical

Working in the lab years ago, I saw 1-Chlorodecane show up now and again when synthesizing bigger, more complicated molecules. Chemical manufacturers reach for it as a starter to make surfactants, flavors, fragrances, and certain lubricants. Its structure makes it useful for designing new substances, especially in specialty chemistry.

Pharmaceutical labs also use it as a stepping stone. Some medications include parts built from simple chlorinated alkanes, often beginning with reactions involving this very compound. The world of flavors and scents wouldn’t be the same without building blocks that look a bit dull alone yet shine once woven into esters and aldehydes. These compounds become the backbone for making artificial fruit notes or industrial cleaning agents that need exactly the right chemical profile.

Strong solvents sit at the center of many manufacturing flows. I once watched production chemists choose 1-Chlorodecane as a model solvent for testing reaction pathways, mainly because it doesn’t interfere easily with other chemicals. In the right hands, that means cleaner final products and less fuss over byproducts.

Handling and Environmental Impact: A Necessary Focus

Concerns don’t end at usefulness. Safety sheets carry warnings for good reason, and I remember more than one safety drill in the plant reminding us of basic good sense—chlorinated compounds can irritate the skin and harm aquatic life. People working with 1-Chlorodecane should use gloves and work in well-ventilated spaces.

Large-scale use often leads to waste. Companies can’t just dump leftovers or wash them down the drain. Regulations require safe disposal, and there’s wisdom behind those rules. Chlorinated alkanes linger in soil and water, risking long-term buildup. In the late 2010s, environmental groups raised alarms about similar compounds popping up in unexpected places. Wastewater treatment upgrades brought improvements, yet discipline on the part of manufacturers makes a big difference.

Moving Toward Safer Chemical Practices

Safer substitutes drive research. Green chemistry’s not a buzzword—industry veterans know switching to less hazardous chemicals can save money and headaches. Solvent manufacturers and researchers work together to design molecules that break down easier or carry less risk out of the gate. In the lab, newer protocols encourage using only what’s needed for each reaction, recycling when possible, and sealing up storage containers tight to keep vapor releases low.

Education works, too. Chemists, engineers, and safety officers need to stay up to date. It’s not enough to know a compound’s use; knowing its hazards and tracking shifting government rules goes just as far. Peer networks, safety trainings, and transparent reporting all support this drive. Addressing risk isn’t once and done—solutions grow as the science moves.

Practical knowledge and commitment to safety keep industries moving forward. With 1-Chlorodecane, that’s the only approach that truly works.Understanding 1-Chlorodecane and Its Place in Everyday Chemistry

Walking through a hardware store or flipping through a textbook, it’s easy to overlook something as simple as a chemical formula. 1-Chlorodecane, with its formula C10H21Cl, might look like just a collection of elements, but there’s real value in knowing what that means. I spent my college years studying organic chemistry, poring over structural diagrams and memorizing formulas like this. It taught me to respect not just the science but also the practical impact compounds like 1-Chlorodecane have out in the world.

Anatomy of a Formula: Breaking Down C10H21Cl

At ten carbon atoms, with 21 hydrogens and a single chlorine tagging onto the end, 1-Chlorodecane reminds me of a long unbroken highway, with chlorine stepping in at the first carbon exit. This structure matters. It controls how the molecule interacts with others. In a lab, such straight-chain compounds play a key role as starting points for building more complex substances. Industries rely on them for reactions that need specific chemical behavior.

Why This Compound Matters in Real Life

I’ve watched 1-Chlorodecane get used in organic synthesis. It can serve as a building block for surfactants, specialty lubricants, or even help researchers model how pollutants move through soil and water. The presence of that single chlorine atom changes how the molecule behaves. It gets a little less friendly with water, more likely to hang out with oils, and much more reactive in certain chemical transformations. This matters not just to chemists, but to anyone interested in how the products in their homes or workplaces get made.

Challenges and Safety Concerns

Working around chemicals like 1-Chlorodecane, I’ve seen how important it is to handle them with care. Chlorinated hydrocarbons have a reputation for lingering in the environment. Plus, while 1-Chlorodecane itself might not be notorious, related compounds tend to show up in discussions about water quality and industrial waste. Strong regulations and good laboratory practice help reduce the risk, but it doesn’t hurt to push for alternatives that break down more easily or come from renewable sources.

The Role of Chemistry Education

Learning the formula for 1-Chlorodecane taught me more than just how to calculate molecular weight. It’s about connecting the dots—seeing how the substitution of one atom can shift an entire molecule’s purpose. As a student, I developed a respect for accuracy and detail. Those skills stick with you, inside and outside the lab.

Pathways Forward

Industries keep moving toward greener processes, and chemists look for ways to design molecules with the same usefulness but less environmental impact. Tools like computer modeling, safer reagents, and thorough education help researchers predict how tweaks to a formula will play out in the real world. The more we understand compounds like 1-Chlorodecane, the better decisions we can make for people and the planet.

What is 1-Chlorodecane?

1-Chlorodecane doesn’t show up in news headlines, but it’s a common ingredient behind the scenes in different industries—think lubricants, cleaning agents, and even research labs. At home, you probably won’t bump into it unless you work somewhere that handles specialty chemicals. Still, it pays to know what risks it carries.

Handling Can Get Risky

The chemical looks like a clear, oily liquid and gives off a sharp odor. Most people’s biggest exposure comes from inhaling fumes, getting it on their skin, or accidental contact with eyes. Personal experience in the lab taught me that gloves and goggles are required, not optional. When my colleague splashed a small amount on his skin, irritation followed fast. Safety data sheets call for quick washing—standard advice for organochlorine chemicals, which can irritate or even cause rashes with repeated contact.

Breathing Matters Most

Breathing in 1-chlorodecane in high enough concentration will irritate your nose and throat. Exposure in tiny amounts might not make you cough or sneeze, but if someone spilled a bottle in a stuffy room, headaches and dizziness could follow. This isn’t a sneaky, invisible threat like radon gas, but its fumes can still hang in the air. I’ve seen coworkers get nosebleeds and queasy feelings after a poorly ventilated experiment. OSHA has not set official exposure limits, yet most companies treat any organochlorine with plenty of respect.

Long-Term Concerns

Regular exposure over months or years poses a bigger question. Studies on 1-chlorodecane itself remain thin, but chemicals in the same family can cause serious health effects—think liver toxicity, nervous system damage, and increased risk of cancer. It doesn’t help that 1-chlorodecane doesn’t break down quickly once it gets into soil or water. Persistent chemicals like this draw the attention of environmental health experts. Once, cleaning up a small spill required sending every rag and glove to a hazardous waste team—nobody took shortcuts.

Possible Solutions for Safer Use

Basic precautions go a long way, so long as they’re followed. In my labs, we stashed 1-chlorodecane in tightly sealed bottles, inside chemical fume hoods. Only trained staff carried the keys. Posting big, clear signs about its risks helped everyone remember not to get casual. Washing hands and careful handling become second nature fast in those settings.

Switching over to less toxic chemicals often gets recommended, but not every process offers an alternative. That means safety training and regular air quality checks become just as important as wearing gloves. Businesses could also add emergency showers and better ventilation where workers deal with large quantities. If you see a chemical spill or start to feel lightheaded, leave the area right away and tell your supervisor. Quick action keeps minor accidents from turning into health scares.

Keeping Public Health in View

Community awareness counts here. Hazardous chemical disposal should stay tightly controlled, so spills or leaks don’t reach water supplies. Every company working with 1-chlorodecane ought to share clear safety information with workers and neighbors. Local clinics benefit from knowing which unusual chemicals factory workers might bring in on their skin or clothes.

Why It Matters

1-chlorodecane sits on a long list of chemicals that rarely draw attention until someone gets hurt. Knowing the hazards, using tight controls, and building a safety culture do more than protect employees—they reassure communities that risky substances won’t become a local health problem. Strong rules, transparency, and hands-on training shape how people stay safe, even around chemicals most folks never see up close.

Getting Close to 1-Chlorodecane

1-Chlorodecane doesn’t show up in most conversations, but you can catch its name in research labs or chemical warehouses. This compound, a chlorinated hydrocarbon, has a pretty long carbon chain for a simple organic molecule—ten carbons, one chlorine atom. Its clear, oily liquid appearance makes it easy to handle in glass bottles, and there’s no splash of color or solid form.

Basic Numbers and What They Mean

Chemists know this compound for its stability at room temperature. Its melting point hovers just below freezing, sitting near -34°C. Not all chemicals play well with cold, but 1-Chlorodecane stays liquid in chilly storage, unlike water which locks up at zero. Pour it in a beaker, and the thermometer needs serious coaxing before anything freezes.

Scale up the heat, and evaporation takes a while; its boiling point lands at about 223°C. That kind of thermal stability lets users heat it up for lab work or testing without fumbling with cooling gear or tight protocols. In a world where solvents and chemicals flash off at the smallest heat, this one keeps its cool—literally.

Solubility and Everyday Handling

Solubility drives so many choices in labs and factories. Water and 1-Chlorodecane don’t mix, a reminder that oil and water-based solutions rarely get along. Try shaking a test tube with both, and you watch layers form instead of the hoped-for mix. In contrast, put 1-Chlorodecane in non-polar solvents like hexane or toluene, and everything blends smoothly. This property shapes how folks use it as a carrier fluid or reactant in organic chemistry.I’ve spilled my share of solvents. 1-Chlorodecane leaves that typical oily residue, quick to wipe but longer to forget if it soaks into gloves. That is the sort of thing many overlook—cleanup and handling often tell you more about a chemical’s “personality” than data sheets ever could.

Density, Odor, and Practicality

A closer look at density shows a value near 0.88 g/cm³. Drop some in water, and it floats—another “oil on water” moment. It doesn’t sting the nose or overwhelm a workspace, with a faint odor that reminds me of walking past a fresh load of plastics rather than a sharp solvent burst. That makes the air around it more bearable for routine use, reducing stress on workers who spend hours in the lab.

Potential Hazards and Thoughtful Handling

Like most chlorinated hydrocarbons, 1-Chlorodecane carries its share of environmental and health warning signs. Prolonged skin contact dries you out; fumes shouldn’t get free rein in a closed room. Chemistry students new to the lab often overlook proper gloves and fume hoods. It’s a smart move to keep the space ventilated and skin covered whenever dealing with this compound.

Disposal remains a practical hurdle. Municipal waste systems won’t take kindly to dumping it down the drain. Responsible labs ship their waste off to specialized treatment plants, where the chemical’s persistence gets managed instead of passed downstream. This sort of attention to the “endgame” often separates responsible use from risky shortcuts.

Room for Safer Substitutes

Using chlorinated solvents in industry has slowly shifted thanks to greener rules and growing care for the environment. Substitutes like linear alcohols or less persistent hydrocarbons pop up whenever process engineers can swap them in. Still, some syntheses or technical tasks lean hard on this compound’s stable, non-reactive nature. Keeping safety front and center makes all the difference—training, protective gear, and a clear waste plan help tie chemical use back to real-world responsibility.

Why 1-Chlorodecane Storage Deserves Attention

Chemical safety often gets overlooked until something goes wrong. I remember a warehouse fire that woke up everyone in my town one winter. All it took was a leaky drum and the wrong temperature. Unlike some household chemicals, 1-chlorodecane brings extra risks. It’s not just about cleaning up spills; poor handling can turn a workday into a real emergency.

Understanding 1-Chlorodecane’s Setup

1-Chlorodecane stands out as a colorless liquid with a boiling point high enough to look safe. This gives a false sense of security, but it still evaporates and releases fumes that can bother the eyes, throat, and lungs. OSHA’s chemical database says that chlorinated alkanes irritate skin, so no one should ignore protective gear. Inhaling its vapors, especially over a long shift, leads to headaches and breathing trouble.

Right Way to Store

My early days in industry taught me the cost of shortcuts. Some techies think any steel drum will do, but not every container plays nice with chlorinated organics. Metal drums with tight seals and chemical-resistant linings matter. The warehouse should feel cool, dry, and well-ventilated. Forget a spot with sunlight— UV rays speed up the breakdown and release of harmful by-products. A shaded, indoor space far from heat sources keeps the liquid stable.

Chemicals next to each other can react in ugly ways. Any facility manager with experience keeps 1-chlorodecane away from strong oxidizers and acids. A spill can grow into toxic fumes or fire. Mark storage areas with warning signs. Walk through at least once a week; check for leaks, vapor odors, and drum corrosion. Any lag in inspection opens up room for disaster.

Handling Without Shortcuts

Workers sometimes skip gloves on hot days, or push aside goggles for a quick task. It’s never worth the risk. Nitrile or neoprene gloves stand up to chlorinated hydrocarbons. Plenty of eye protection and splash-proof aprons keep skin from itch or burn. A chemical fume hood or exhaust fan removes lingering vapors. Eye wash stations and showers must sit within easy reach, not hidden behind boxes.

Anyone who moves or transfers this liquid should double-check labels. Pumps made of PVC or stainless steel handle the job better than rubber hoses, which might break down and leak. Keep spill kits nearby, with absorbents, neutralizers, and containers for quick cleanup. Emergencies turn small mistakes into headlines. Training drills beat panic, and everyone should stay ready to use respirators if things get out of control.

Room for Improvement

Many companies get stuck in old habits. Bringing in digital sensors or chemical-resistant flooring could dodge expensive cleanups. Insurance companies reward upgraded storage. Local firefighters know which drums hold the biggest risks if a call comes in at 3 A.M. These moves cost less than downtime or injury lawsuits.

Building a culture of respect around chemicals like 1-chlorodecane pays off year after year. A safe team feels more confident, more valued, and more ready for whatever tricky liquid comes through the door next.