2-Bromobutane: A Comprehensive Commentary

Historical Development

In the story of chemical synthesis, 2-bromobutane holds a place as a workhorse for teaching and industrial processes. Through the late 1800s and early 1900s, chemists started looking for reliable halogenated hydrocarbons to use as reagents, solvents, and building blocks. The preparation methods for alkyl bromides like 2-bromobutane linked directly with the rise of organic labs in universities and the early boom of petrochemistry. As industries turned to petroleum, straightforward methods to derive brominated compounds from butane and butenes became crucial, especially for applications that demanded reactivity or selectivity otherwise tough to achieve with simpler hydrocarbons.

Product Overview

2-Bromobutane comes across as a clear and colorless liquid, typically bottled in amber glass or sturdy plastics to avoid light-induced decomposition. Its strong, biting odor often reminds one of ordinary solvents, yet it’s more than just an odorous bottle on a shelf. Across chemical manufacturing, 2-bromobutane takes on roles in synthesis as an alkylating agent, a precursor for Grignard reagents, and a substrate for substitution and elimination reactions. You’ll find it present in undergraduate labs for hands-on organic lessons and in pharmaceutical plants as part of multi-step syntheses.

Physical & Chemical Properties

A closer look at its characteristics reveals a boiling point around 91°C, which presents a fire hazard in labs without ventilation. Its density runs heavier than water, about 1.26 g/cm³ at room temperature, and it sinks quickly if spilled. Solubility in water is low, but 2-bromobutane miscibly blends with organic solvents. Its refractive index hovers near 1.437, so chemists run purity checks using handheld refractometers. Flammability marks one of its major risks, but the chief concern is volatility and ease of inhalation, turning simple handling into a lesson in lab discipline.

Technical Specifications & Labeling

Bottles of 2-bromobutane arrive with a GHS-compliant label featuring CAS number 78-76-2, hazard pictograms for flammability and acute toxicity, and full signal words such as “Danger.” Producers report assay purity often at 98% or higher, and impurities—mostly lighter butanes or dibromides—get tested using gas chromatography. Chemical suppliers include UN numbers for transport (UN 2349), and the material’s SDS warns about skin absorption, eye contact, and long-term effects like organ toxicity. Labs have trained techs confirm every shipment by NMR or GC-MS, since isomers or bromide contamination can sharply affect research results.

Preparation Method

One of the most hands-on preparative methods takes 2-butanol and reacts it with hydrobromic acid, sometimes with sulfuric acid as a catalyst. In practical runs, chemists cool the mixture to balance yield and minimize byproduct formation. After shaking the mixture in a separatory funnel, the brominated product settles out, ready for distillation. This approach, besides being efficient, carves out 2-bromobutane selectively due to the secondary alcohol’s higher reactivity compared to primary isomers. On a larger scale, industrial plants use butene mixed with hydrogen bromide gas to achieve higher throughput in continuous-flow setups. Every synthetic route triggers byproducts—like dibromobutane and brominated ethers—requiring careful fractionation and waste management.

Chemical Reactions & Modifications

2-Bromobutane stands at the crossroads of classic organic transformations. In the SN2 reaction with sodium cyanide, chemists swap the bromine group for a nitrile, unlocking a path to valuable amines after reduction. The molecule’s secondary carbon can also trigger E2 eliminations if stronger bases mix in—sodium ethoxide shifts it toward 2-butene as a major product. One challenge in research settings deals with competing pathways; students often discover how temperature and concentration drive substitution versus elimination, giving a practical demonstration of kinetic and thermodynamic control. The bromine atom’s leaving ability aids not just substitutions but the preparation of Grignard reagents. Magnesium turnings transform 2-bromobutane in ether to forge a secondary alkyl magnesium bromide, a staple C–C bond-forming species in synthesis exploration. Secondary alkyl bromides see less use in radical reactions, but photolytic conditions with suitable initiators can break the C–Br bond for targeted functionalizations.

Synonyms & Product Names

Anyone searching supply catalogs might stumble across names like sec-butyl bromide, or 2-butyl bromide. These aliases stem from the molecule’s branching; the bromine hooks onto the second carbon, making it a secondary bromide. Old lab manuals sometimes refer to it as methylpropyl bromide. International safety sheets and shipping records frequently abbreviate the name to 2-BB, but product bottles need the full systematic label to clear customs or cross academic boundaries.

Safety & Operational Standards

Handling 2-bromobutane puts a premium on vigilance. Vapor inhalation brings acute symptoms: headache, dizziness, respiratory tract irritation. Skin and eye contact burn fast, and chronic exposure risks organ damage according to animal studies and IARC listings. Modern operational standards stress chemical fume hoods, disposable nitrile gloves, and eye protection. Every bench worker keeps spill kits ready, and local exhaust captures released vapors. Many facilities require periodic air monitoring, ensuring levels stay well under short-term exposure limits. Fire departments know that 2-bromobutane spills ignite easily above 20°C, so firefighting gear must fit chemical hazard profiles—not just wet blankets but foam extinguishers. Waste disposal never heads down the sink; halogenated liquid waste collects in labeled containers, destined for incineration under controlled conditions.

Application Area

2-Bromobutane’s reach in synthetic chemistry is vast. Medicinal chemists tweak starting structures, using the sec-butyl bromide group to build chiral intermediates for drugs targeting rare diseases. Agrochemical labs explore it as a synthon for insecticidal or fungicidal candidates. In material science, adjusting alkyl bromide content tunes polymer properties for adhesives or specialty plastics. Analytical labs use it for method development, calibrating GC columns for separation of light hydrocarbons. For years, its physical properties helped undergraduate students practice distillation, substitution, and stereochemistry, grounding theory with direct experience.

Research & Development

Recent R&D efforts focus on asymmetric synthesis using chiral bases or catalysts, coaxing 2-bromobutane toward enantioselective products. Solid-supported reagents and greener solvents lead to safer and more sustainable workflows, addressing not just yield but environmental load. Chemoinformatics platforms track reactivity patterns, predicting new reaction partners for straightforward functionalization. At the interface of academia and industry, teams develop flow chemistry tools that integrate continuous monitoring with robust safety interlocks, shrinking downtime and reducing losses. Digital logs and laboratory information management systems catalog every batch, from the moment raw 2-bromobutane arrives to its use in pilot plant validation.

Toxicity Research

Toxicological data indicate that 2-bromobutane defies simple categorization. Acute exposure mostly irritates mucous membranes and skin. Longer studies on rodents reveal hepatotoxic effects at repeated or high doses; the brominated hydrocarbon group often forms reactive intermediates in the liver, leading to cellular injury. Inhalation trials with higher vapor concentrations demonstrate a potential for central nervous system depression, but at realistic lab exposure levels with controls in place, incidents rarely go beyond temporary discomfort. Environmental persistence should not be overlooked—runoff or accidental discharge into water can disrupt aquatic species and bioaccumulate in the ecosystem. Regulatory agencies, including the EPA and ECHA, require comprehensive safety data for any new application scenario, driving ongoing research into chronic and reproductive effects.

Future Prospects

As chemical manufacturing grows more sophisticated, the place for 2-bromobutane evolves. Demand for targeted, stereoselective synthesis in pharmaceuticals and advanced materials forecasts steady growth in secondary alkyl bromides. Researchers push for less hazardous preparation and disposal methods, leveraging solvent recovery and byproduct recycling. Some startups invest in continuous flow photochemistry, boosting safety and shaving raw material costs. On the education front, remote-controlled micro-labs let students run classic substitution reactions in a virtual setting, keeping risks low while emphasizing core concepts. Environmental priorities nudge producers to adopt renewable feedstocks and lower-impact bromination methods, aiming for protocols that lower emissions and worker hazard without sacrificing quality. Watching these trends, it’s clear that 2-bromobutane’s legacy will shift from routine reagent to benchmark for smart, safe, and responsible chemical design.

Chemistry Beyond the Classroom

The first time I walked into an organic chemistry lab, the sharp scent of solvents told me I had left the world of textbooks behind. Among the chemical bottles marked with cryptic names like “2-Bromobutane,” I realized that chemicals we barely hear about still shape the research and technology that surround us. Many students learn about 2-Bromobutane as a mere footnote during lessons about substitution and elimination reactions, but there’s more here than meets the eye.

Key Uses of 2-Bromobutane

2-Bromobutane stands out as a practical alkyl halide that allows researchers to make critical building blocks for bigger things, from medicines to plastics. In labs, it gets added to a flask, ready to participate in “SN2” or “SN1” reactions—terms that might scare away most people who disliked chemistry. In practice, these reactions help scientists replace the bromine atom on the molecule with another group, making it easy to build complex molecules.

I used 2-Bromobutane in my own graduate research. We treated it with sodium cyanide, turning it into 2-cyanobutane, which later transformed into an amine for a potential anti-inflammatory drug. The convenience of this approach can save days compared to starting from scratch. The pharmaceutical industry applies similar strategies, using 2-Bromobutane as a stepping stone toward drugs used to treat conditions many of us care about, such as heart disease and depression.

In the classroom, professors unravel mysteries of chemical mechanisms with 2-Bromobutane as their hero. Its structure helps teach students how two nearly identical molecules can behave differently—a lesson in stereochemistry. Students watch how substitution and elimination compete, and how temperature, concentration, and the choice of solvent influence the outcome. Knowledge like this gives future chemists the know-how to solve real-world problems.

The Environmental and Safety Side

People rarely think about what happens after a lab session wraps up. The bottle of 2-Bromobutane comes with a warning label for good reason. It carries risks if not handled right—skin, eyes, and lungs react poorly to exposure. Spills or improper disposal can cause trouble downstream in the environment. In my lab, following safe storage guidelines meant limiting the amount on the shelf, keeping a fume hood running, and logging every use.

Regulators put controls in place to keep things safe, requiring manufacturers to respect strict handling guidelines. Tracking usage and disposal helps protect the public and avoids the small mistakes that can add up to bigger environmental risks. Routine training in chemical hygiene lets even those new to the lab avoid trouble.

Innovation and the Path Forward

As innovation races ahead, researchers look for greener ways to achieve the same chemical transformations that 2-Bromobutane makes possible. Companies invest in alternative reagents and cleaner processes to cut down on waste. While the traditional approach keeps a foothold thanks to its reliability and cost, the move toward sustainable chemistry grows stronger each year. Those of us who’ve spent hours with safety goggles and pipettes hope future labs blend safety, practicality, and environmental care.

Closing Thoughts

From the outside, 2-Bromobutane doesn’t look like a star—its role, tucked away in glass bottles, stays quiet. Yet, every time I see a drug label or plastic material, I remember the small steps and overlooked reagents that make big changes possible. If chemistry is about building blocks and connections, then 2-Bromobutane plays a role no one should ignore.

What Makes 2-Bromobutane a Concern?

Once a substance turns up in high school chemistry labs and industrial settings, safety questions start popping up. 2-Bromobutane, a clear liquid with a faint odor, always deserved caution. After spending years as a technician in a chemical storage warehouse, mishandling this stuff sticks in my memory — nobody wants to repeat those mistakes. Flammability and overall hazard often come up, especially when young workers first meet these bottles on warehouse shelves.

Flammability: Not Off the Hook

2-Bromobutane catches fire. Most folks don’t expect a halogenated hydrocarbon to burn as easily as gasoline, but it surprises people. With a flash point just under room temperature (about 24°C or 75°F), it doesn’t take much warmth or a random spark to make trouble. A worker I supervised years ago spilled some on a bench under a heat lamp. The resulting flame licked up the side of a shelf faster than his reflexes. Fire extinguishers stopped the spread, but nerves ran high for hours. Safety data always rates 2-Bromobutane as flammable for a reason. Labs keep it in tightly sealed bottles, away from open flames and even windows that let sunshine heat up the workspace.

Breathing and Touching: Not Just Burn Hazards

Flammability catches attention, yet direct contact or inhalation is the real threat for most people. Exposure brings headaches, dizziness, and irritation. Without gloves and eye protection, skin gets red, and eyes start watering. Once, during a basic distillation exercise, a classmate skipped the lab coat and fumbled with a dripping glass dropper. He spent the afternoon rinsing his wrist under running water — lesson learned, pain not forgotten. Spills on skin require quick washing. The liquid releases vapors too, which hang around at floor level thanks to its density. Working in a closed-off storage shed, I saw the results of carelessness. Two workers insisted the area was safe without ventilation, then complained about nausea before lunch. An open window stopped future incidents, but health shouldn’t depend on luck or hindsight.

Storage and Handling: Preventing the Problems

Shelves crammed with reactive substances often end up smelling odd because vapors sneak through imperfect lids. 2-Bromobutane asks for tighter controls. Chemical-resistant gloves and goggles make a difference. Keeping it far from oxidizers or strong bases drops the risk. I saw a co-worker stack incompatible bottles to save shelf space; a minor leak threatened a major mess. Separation by substance type makes more sense than packing for convenience. Dedicated flame-proof cabinets help. If the space lacks extraction fans or basic spill kits, expect trouble — sooner rather than later.

Solutions That Work

Solutions exist, just not shortcuts. Good training matters. Workers need refreshers, especially before handling hazardous liquids. Quick clean-up tools close to the storage site save time in emergencies. Labeling every container with hazard symbols prevents nasty surprises, especially when old bottles lose their print or sit on shelves for years. I always liked the “buddy system” on busy days; nobody worked alone, so someone always noticed and fixed sloppy habits. Regular audits of chemical stocks highlight leaks and force action before minor problems become serious news stories.

Why It Matters

Personal experience counts because workers rarely memorize numbers from safety sheets but remember real accidents. 2-Bromobutane burns, hurts on contact, and won’t forgive lazy storage. Clear procedures, good ventilation, and upfront respect for risk let folks handle hazardous chemicals and make it home in one piece. Looking out for the person next to you is the key lesson I took from handling this liquid. That lesson outweighs any statistics on a dusty data sheet.

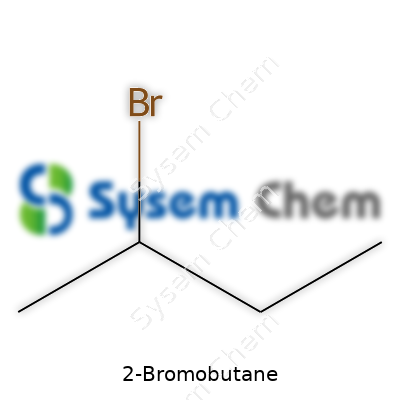

Understanding the Basics

Step into any high school lab, and you’ll notice how some molecules get tossed around like old friends. 2-Bromobutane is one of those names that lingers in the air during organic chemistry lessons. At its most basic, this molecule comes from butane. Add a bromine atom, and everything shifts. The molecular formula for 2-bromobutane is C4H9Br. Nothing fancy—just four carbons, nine hydrogens, and a bromine.

Why Details Matter in Chemistry

To someone out of the loop, listing carbons and hydrogens might feel tedious. The fact is, specificity keeps chemists honest. I remember mixing chemicals in college and realizing how quickly things change when you swap out even one atom. Imagine expecting table salt and getting bleach; the tiniest variation turns everyday substances into something dramatically different or even dangerous. In practice, knowing the formula prevents accidents and helps direct research for new medicines, materials, and sustainable fuels.

The Human Side of Organic Molecules

For many years, I ran a small tutoring group. New students often struggled with molecular formulas. Once they saw how structure connects to function—and how a single atom can alter a compound’s role—their curiosity caught fire. 2-Bromobutane isn’t just a pile of atoms; it carries different properties than the straight butane found in lighters. Take its use in the synthesis of pharmaceuticals and agrochemicals. Without an exact formula on hand, labs risk expensive errors and safety hazards. Mistakes like these can spiral, affecting jobs, budgets, and health.

Why Do We Even Need This Compound?

The applications reach farther than most expect. 2-Bromobutane serves as a starting point for making other chemicals, especially those needed in drug synthesis. In my early work, our team relied on it to add a bromine to carbon chains, which opens doors for more complex reactions. Its presence lets researchers build molecules with tailored effects, whether fighting bugs on crops or battling illness. Each new breakthrough depends on careful planning and precision. Without respect for the molecular formula, none of that holds together.

Learning From the Details

Every time I explain C4H9Br, I see one lesson stick: paying attention beats guessing. Stories from the field reinforce this. One time, a friend’s lab received a delivery mislabeled as a similar compound. That slight deviation set their project back by weeks, costing money and morale. Standards exist to keep these problems at bay, but human eyes catch what machines might miss.

Solutions and Takeaways

Teaching clear principles—like how each molecular formula spells out structure—helps everyone in the chain, from student to scientist. Simple diagrams and hands-on practice make a big impact. Backed by experience, this direct approach teaches respect for the foundational details that guide bigger breakthroughs. With accurate information about molecules like 2-bromobutane, labs can safely push the boundaries of chemistry. Data transparency, good labeling, and a habit for double-checking can save time and prevent accidents, both in the classroom and industry.

Why It Matters

Anyone who’s handled chemicals in a lab knows that storage shapes safety as much as procedure. 2-Bromobutane seems like a simple organic compound, but ignoring its quirks can lead to avoidable risks. Over the years, I’ve seen even experienced colleagues trip up with substances as straightforward as this. One small mistake can ruin weeks of hard work—or worse, put people at risk of exposure.

Understanding the Risks

2-Bromobutane has a reputation for volatility. Its low flash point and vapor pressure tell the story: this liquid can evaporate easily and ignite at lower temperatures than you may expect. Even the odor, sharp and noticeable, warns that fumes escape quickly. Those vapors aren’t just a nuisance; they affect indoor air and create fire hazards. Long-term exposure isn’t a joke either—it can irritate skin, eyes, and lungs. Proper storage acts as a frontline defense. You never want to scramble after a spill or see that familiar label in an unexpected place.

Lessons From the Field

Too often, busy labs leave chemicals on benchtops or in generic cabinets. That rough-and-ready approach lands people in trouble. I recall a stint in a teaching lab where someone left a bottle of 2-Bromobutane in sunlight, which led to noticeable degradation. Its color changed and, crucially, a pungent smell developed further, prompting an evacuation. These real-world slip-ups drive home how storage lessons must become habit, not afterthought.

Solid Storage Practices

The right storage for 2-Bromobutane begins with a tightly sealed, chemical-resistant container. Glass, with a proper lid, works far better than plastic, since certain plastics can degrade or let the vapor escape. Find that cool, dry, and dark spot in your dedicated flammable cabinet—not a shelf by the window or a section above a radiator. Many labs use cabinets with fire-resistant properties for these volatile organics. Safety Data Sheets from manufacturers stress this same point, and for good reason—such cabinets buy precious time if a fire breaks out.

Spill trays add another layer of security, cutting down on leaks and making clean-up faster. I’d recommend labeling every container clearly, with both name and hazard warnings visible. In my time, clear labeling proved itself again and again—especially when staff turnover left new faces unfamiliar with old bottles in shared storage.

Avoiding Cross-Contamination

Storing 2-Bromobutane away from acids, oxidizers, and open flames brings peace of mind. Chemical incompatibilities rarely announce themselves beforehand. Even small vapors can trigger reactions with the wrong neighbors. The National Fire Protection Association classifies 2-Bromobutane as a Class IB flammable liquid, so its storage area should support grounding and bonding of containers when transferring.

Ventilation plays a role, too. A room with a fume hood, or at least exhaust fans, keeps vapor levels down and protects those in the space. If your facility doesn’t have this luxury, at least keep containers closed tightly and access limited to trained folks. Regular inventory checks help spot aging bottles or any signs of breach.

Continuous Improvement

Experience teaches that protocols without reminders slip from memory. Training sessions, visible charts, and checklists keep the standards fresh for new team members and veterans alike. I’ve seen teams forget storage guidelines until an inspection looms. Bringing the details up regularly sidesteps that rush and puts safety on autopilot.

Why 2-Bromobutane Deserves Respect in the Lab

2-Bromobutane turns up often in organic labs, especially during synthesis and teaching work. It brings convenience, but every chemist quickly learns that its sharp, sweetish odor isn’t just a warning — it’s a real sign to get serious about protection. My own experience with it came in the second year of chemistry class, and after one careless splash, I learned fast how a little lapse could sting your skin or make breathing tough for hours. Chemical safety really becomes personal once you get a whiff.

What Personal Protection Actually Means

Everyone knows about gloves and coats, but too many folks treat them like just another dress code. 2-Bromobutane can irritate skin, hurt your eyes, and harm your lungs. I always reach for nitrile gloves, not the thin latex ones. Lab coats with decent cuffs keep arms safe, and goggles — not just glasses — shield against accidental spray. Now, some colleagues shrug off fume hoods for “quick” transfers or when the smell seems faint. But 2-Bromobutane forms vapor easily, and nobody should risk breathing in organics. Real safety starts with making sure every bit of the process takes place under extraction, hood sash pulled low, fresh airflow running.

What Spills and Storage Look Like in Real Life

Spills might seem rare, yet it only takes one wobbly transfer to put everyone at risk. I always keep absorbent pads and neutralizing agents within reach — paper towels alone don’t cut it. If a bottle tips, the right response means opening windows, signaling others, and cleaning up with gloves and double-sealed bags. Leaving the area quickly and notifying the supervisor stays at the top of my list. For storage, 2-bromobutane belongs tightly capped in a chemical cabinet away from sunlight and heat. Flammable-proof cabinets aren't just expensive steel boxes; they save real headaches by stopping leaks and temperature swings. I take inventory every week, making sure labels remain legible, bottles clean, and nothing leaks. Simple routine, but it pays every time.

Our Health and Why Ventilation Really Matters

I remember one summer day, the AC failed and the air in the lab grew heavy. Even a minor whiff of 2-bromobutane left some students dizzy. The lesson: good air exchange isn’t an extra feature, it’s core to working safely. Long-term exposure risks go beyond coughing — chronic inhalation can hurt livers and nervous systems. The U.S. National Library of Medicine and NIOSH recommend exposure limits for good reason, so I always remind myself to check airflow before anything else. Signing out keys for the chemical storage or opening another ampoule starts with a glance at the fume hood gauge — not just habit, but peace of mind.

What Solutions Make a Safer Lab?

I’ve seen big improvements since my first year in chemistry: QR code SOPs by every hood, safety reminder posters right above weighing stations, and proper toxicity data easy to check online. Real gains come from trained people, not just rules. Peer-checks work — sometimes a sharp eye from a lab-mate saves a bad day. Monthly refreshers and emergency drills keep everyone sharp. My advice: treat 2-bromobutane with the seriousness you’d show any strong chemical, remember the last incident you read about, and take comfort that with these steps, most accidents can be avoided.