Allyl Bromide: Development, Properties, Applications, and Future Insights

Historical Development

Chemistry has always been about taking small ideas and turning them into building blocks for something bigger. Allyl bromide, a colorless liquid with the catchy formula C3H5Br, represents one of those blocks that shaped organic synthesis for decades. Researchers in the 19th century first isolated compounds like this through direct reactions involving elemental halogens and unsaturated compounds. The early chemists didn’t have today’s safety standards or analytical tools, but their consistent efforts to understand how unsaturated hydrocarbons behave led to the identification of reactive intermediates like allyl bromide. As the study of electrophilic addition developed, this compound quickly found its place in both research and commercial settings. Organic chemists saw its potential for creating carbon-carbon bonds and harnessing its alkylating properties, pushing its industrial-scale production through the 20th century.

Product Overview

Allyl bromide enters the scene as a highly reactive compound, favored for its affinity to react with nucleophiles. Clear and volatile, this compound releases a sharp, irritating odor that signals its potency even in a well-ventilated lab. Laboratories and factories see it as more than a simple halide; it’s a versatile starting material. With a boiling point just under 72°C, it remains manageable under standard conditions, but demands close attention every step of the way. In practice, many chemists use it to introduce an allyl group into a wide array of chemicals—from agrochemical intermediates to specialty polymers—bridging the gap between raw petrochemical feedstocks and high-value products.

Physical & Chemical Properties

Allyl bromide carries a molecular weight of around 120.98 g/mol, lending it stability for easy handling, yet making it light enough for volatile behavior at room temperature. Water doesn’t dissolve much of it, which means spills don’t spread quickly in lab sinks, but it easily dissolves in organic solvents such as ether, chloroform, and acetone. The density lands at roughly 1.398 g/cm3, higher than water, so any mixture clearly divides into two phases. Its refractive index hovers around 1.464, and the vapor pressure at room temperature reminds every handler to keep containers sealed tightly. Chemically, the presence of the reactive bromine atom next to the allyl group renders the molecule an excellent electrophile. Anyone who has worked at the bench knows that reactions with nucleophiles, like amines or thiols, progress rapidly and often exothermically.

Technical Specifications & Labeling

Chemicals have to move through supply chains in a safe, traceable manner. Allyl bromide comes in tightly sealed amber glass bottles or sturdy metal drums, marked with hazard and purity information front and center. Labs receive product ranging typically from 98% to 99% purity, and suppliers provide detailed certificates of analysis. Globally recognized label codes flag its toxicity, flammability, and environmental hazards without room for ambiguity. On every drum or bottle, you’ll see warnings against skin, eye, and respiratory contact, as exposure even to the vapor often brings immediate irritation. Regulators like OSHA, REACH, and GHS have clear criteria for its storage, transport, and disposal, all of which suppliers reference directly. A standard kit includes batch number, CAS registry number (106-95-6), manufacturer’s name, handling instructions, and emergency contact.

Preparation Method

Preparation in industry usually involves reaction of allyl alcohol with hydrobromic acid or phosphorus tribromide, producing the bromide alongside byproducts like water or phosphorus acid. Small labs favor this route, since allyl alcohol itself can be made from propene—a common petrochemical. Mixing and cooling are key, since runaway heat can send vapors through a poorly vented fume hood or even lead to dangerous side products. Once formed, the product splits off and is typically purified by distillation, sometimes over calcium chloride to sweep away traces of water. The reaction runs clean, though leftover acids need neutralizing and careful disposal. Industrial set-ups feature closed systems, scrubbers, and recovery condensers to curb emissions and protect both workers and the neighborhood outside the plant.

Chemical Reactions & Modifications

Allyl bromide has never been a one-trick pony in synthetic chemistry circles. Its most important use comes from serving as an alkylating agent—a tool for stretching carbon frameworks by coupling with nucleophilic partners. The allyl group, thanks to resonance stabilization, opens the door to everything from SN2 substitutions to telomerizations. Lab teams lean on it for preparing protected derivatives of alcohols and amines, creating ethers or amides in a click. Grignard reagents readily react with allyl bromide, giving access to longer carbon chains or offering a shortcut to substituted cyclopropanes. Working with it, you notice the compound’s knack for forming C–C and C–N bonds, which finds use across pharmaceuticals, agrochemicals, and advanced materials. Sometimes, teams modify its properties by playing with its double bond in cycloaddition or metathesis reactions, constantly searching for new catalysts and efficiencies.

Synonyms & Product Names

Scientists and traders list allyl bromide under a stack of synonyms, reflecting how language and chemistry cross paths in catalogs and regulatory papers. Common names include 3-Bromopropene, 1-Bromo-2-propene, and bromallylene. In older literature, you’ll see references to propene, 3-bromo-; such diversity in names proves handy for pulling research from different databases or regulatory bodies. Chemical suppliers often market it under these names, making cross-reference essential during purchasing or literature review. Safety sheets usually bundle all these synonyms for clarity, sparing users the confusion of tracking multiple identifiers for the same volatile bottle on their shelves.

Safety & Operational Standards

Allyl bromide falls squarely into the category of chemicals you treat with utmost respect. Exposure brings immediate risks—skin burns, severe eye irritation, sore throats, and acute breathing problems, all within minutes. Working with it in the lab, I always double-check my gloves, goggles, and ventilation, since the pungent vapor finds its way through the smallest crack. Engineers in industrial plants don full protective gear, and monitor exposure levels around the clock. Storage keeps drums locked in cool, well-ventilated areas, always far from ignition sources. Fire isn’t just a theoretical risk; the low flash point turns spills into flash fires if mixed with static or open flames. Standard response to a spill involves traps, sand, and well-drilled evacuation plans. Emergency protocols focus on speedy decontamination and getting exposed folks to fresh air before symptoms worsen. In short, experience teaches you not to cut corners.

Application Area

Allyl bromide books its main roles in making specialty chemicals and polymers, but the real spread of its uses goes further. Big pharma uses it for synthesis of intermediate molecules on the road to antifungals, antibiotics, and analgesic agents, where it kicks off complex coupling reactions that build intricate skeletons. Agrochemical folks rely on it to craft herbicides, fungicides, and insecticidal ingredients, since its reactivity speeds up multi-step processes. Some advanced materials teams put it to work in customized polymer architectures—think ion-exchange resins, high-impact plastics, or flame retardants with unique functional groups. On the academic side, researchers draw on allyl bromide to explore radical chemistry, organometallics, or to generate molecular probes for tracking biological pathways. Such a broad spectrum explains its continued production and near-ubiquitous presence in synthetic labs worldwide.

Research & Development

Research surrounding allyl bromide constantly takes on ambitious targets. New catalysts and greener reagents aim to lower energy consumption during its synthesis and application. Academic groups hunt for selective activation of the allyl group under milder or less hazardous conditions, hoping to expand the toolkit for drug and materials development. Engineers put effort into process intensification—building flow chemistry systems that scale safely, recycling waste, or capturing bromine for reuse. Analytical chemists make use of the molecule as a probe, tweaking isotopic labels to follow mechanisms in real time. Efforts to substitute more sustainable solvents or to cut emissions push regulators and practitioners alike toward tighter controls and cleaner practices. At every conference, I hear folks swapping notes about improved yields, better selectivity, and cutting down exposure risks without sacrificing output.

Toxicity Research

Toxicologists take a close interest in allyl bromide, since its acute hazards demand continuous vigilance. Laboratory and animal studies reveal that vapor or prolonged skin contact inflicts both immediate and long-term health consequences, such as tissue damage, respiratory sensitization, and central nervous system effects in high concentrations. Regulatory agencies classify it squarely as hazardous, and workplace exposure limits reflect a low threshold. Epidemiological studies among chemical plant workers highlight the importance of strict ventilation, leak monitoring, and decontamination routines. Wastewater containing residual allyl bromide can’t just flow into municipal systems. Most research into detoxification zeroes in on rapid breakdown routes—neutralization with alkali, photolysis, or advanced oxidation to convert allyl bromide into safer end products before effluent release. Ongoing animal toxicity studies guide how regulators set new thresholds and push industries to innovate safer processes.

Future Prospects

The future of allyl bromide links to the ongoing transformation of both the chemical industry and environmental policy. With growing pressure to green up production, research pivots toward better catalysts, higher atom-economy routes, and renewable feedstocks for both allyl alcohol and hydrobromic acid. Some hope to phase out brominated intermediates in favor of less hazardous alternatives; yet, the robust reactivity profile keeps allyl bromide in demand for many high-value syntheses. I expect machine-assisted reaction monitoring and process control to reduce incident rates and allow finer tuning of reactions, making this compound safer to handle on a large scale. As pharmaceuticals, advanced polymers, and novel agrochemicals continue rising, manufacturers stay motivated to keep improving safety, efficiency, and environmental records around its lifecycle. Young researchers and industry veterans alike keep finding new ways to use and handle allyl bromide, pushing chemistry’s boundaries unquestioningly onward.

What Allyl Bromide Brings to the Table

Allyl bromide often shows up in labs and factories, quietly playing a key role in getting chemical reactions underway. If you’ve studied chemistry or walked through a research facility, you’ll know there are certain powders and liquids with strong odors and strict handling guidelines. Allyl bromide stands out among them with its sharp, spicy smell and notorious impact on the eyes and skin. It isn’t the kind of chemical people mess around with for fun; most places lock it up with clear safety warnings.

Real Impact in Pharmaceuticals and Research

In drug synthesis, allyl bromide is a building block—a chemical you need to attach certain groups onto other molecules. Drug makers use it to make compounds that go into antifungal, antiviral, and anti-inflammatory medicines. It can change how a drug behaves in the body, making treatments more reliable or targeting specific problems. There’s always a balance between speed and safety during chemical reactions, and allyl bromide gets the job done fast without complicating purification too much. Labs also use it in small-scale research, testing new ways to fight disease or assemble advanced materials. I’ve seen researchers light up when a batch finally works because they managed to add an allyl group exactly where they wanted using this chemical.

Everyday Products Owe a Lot to Simple Chemicals

Beyond medicine, allyl bromide shapes the start of all sorts of materials. Take plastics, resins, and adhesives—the kind that keeps furniture together or insulates your electronics. The backbone of many polymers and resins shows the fingerprint of reactions started by this compound. Older textbooks mention paints and coatings, and the same chemistry still pops up in factories trying to develop more environmentally friendly finishes. My time in a coatings workshop taught me that some of the toughest challenges aren’t about what the final product looks like, but whether the starting materials behave as expected every step of the way. Allyl bromide doesn’t get much limelight, but when it acts up or is replaced with inferior alternatives, production lines feel the pain—extra costs, missed deadlines, frustrated teams.

Risks, Regulations, and Responsible Handling

Safety with allyl bromide deserves respect. This chemical irritates the skin and eyes in an instant; a quick splash can ruin someone’s day or require a hospital visit. In some cases, the fumes have caused headaches or nausea in nearby workers. Agencies like OSHA and the European Chemicals Agency set strict exposure limits and recommend protective equipment for anyone handling or transporting it. There’s no room for cutting corners here. Even waste from reactions involving allyl bromide gets separate handling so it doesn’t end up in water or soil, where it could threaten nearby communities. I’ve seen real improvement in facilities that train people thoroughly on these protocols—cutting spills to near zero, boosting confidence, and keeping the workplace safer for everyone.

Moving Forward: Alternatives and Innovation

Chemical safety regulations grow tighter every year, pushing companies to seek alternatives. Some research groups test less hazardous bromides or look for greener routes that skip bromine altogether. These projects are expensive, but as someone who’s dealt with both old-school hazards and new eco-friendly materials, I know the long-term benefits outweigh the headaches. Many universities link up with industry to search for smarter, safer ways to achieve the same chemical tweaks, sharing breakthroughs with a global network. It’s work that rarely makes headlines, but those efforts lay the foundation for safer labs, healthier workers, and greener products on the shelf.

Why Allyl Bromide Raises Concerns

Allyl bromide isn’t the kind of chemical you want to be casual about. It’s clear, it smells, and exposure can hit your body in nasty ways. Skin blisters, eye irritation, trouble breathing—those all become real threats if you treat this stuff like water. Years of working around organic chemicals taught me that even the friendliest lab can turn into a triage center if someone skips basic safety. Checking safety data sheets once is never enough. You need to treat the risks as part of the process, not just an afterthought before lunch.

Gearing Up Is Step One

Latex or nitrile gloves, not the vinyl kind, help keep allyl bromide off your hands. I learned quickly after a colleague ended up with a chemical burn through a thin glove that skimping on gear only leads to pain. Laboratory coats and flame-resistant aprons keep your skin and body covered. Even if a single drop seems harmless, it rarely stops at one. Splashing echoes further than you expect. Eye protection means goggles, not just glasses. Regular safety glasses don't shield you from a splatter that bounces off a flat surface.

Breathing Freely Should Matter

Inhaling this chemical stings the throat and does even more damage down the line. You want a chemical fume hood doing the heavy lifting, not a cracked window. I’ve seen too many folks lean in out of laziness, only to choke and cough for hours. Respirators offer a backup if the hood’s airflow isn’t up to snuff. It’s always better to overdo it on ventilation than regret it five hours later in urgent care.

Know Where You're Working

Crowded, poorly ventilated spaces are dangerous territories for handling allyl bromide. You want solid, non-porous benches that are easy to wipe down after spills. Spills aren’t rare—they happen. I remember a time someone ignored a tiny leak from a transfer pipette. Within minutes, the smell punched through the room. We locked it down fast, but it hammered home the lesson that quick, decisive spill management saves skin, lungs, and sometimes whole lab days.

Storage Isn’t Optional

Allyl bromide reacts fast with water and doesn’t play nice with strong bases. It lives best in tightly sealed glass containers, away from busy hands and heat sources. A dry cabinet, tucked far from acids and anything reactive, reduces panic if a bottle tips over. I grew used to checking the labels twice and scanning for leaks every morning before flicking any lights on.

Training and Emergency Basics

No matter how smart you are, rushing will burn you. Regular training, even if it feels repetitive, drills in those habits that stop problems before they start. Emergency showers and eyewash stations must stay clean and uncrowded. Buddy systems help in a pinch—one person reacts while the other calls for help. A close friend once saved her own eyesight because another tech knew exactly which lever to pull without hesitation.

Improving Lab Culture Matters

No safety measure has full impact without a culture that prioritizes health. Peer checks, open reporting of near-misses, and reward systems for clean workstations build habits. All it takes is one slip for everyone to feel the consequences. Most labs run on teamwork—collective vigilance keeps people safe. Good companies and schools base their routines on accident-free records, not just throughput.

Allyl bromide brings plenty of potential, but only to those who show respect. Personal protection, ventilation, storage, quick action, and steady attention—these are what separate safe learning and discovery from regretful accidents.

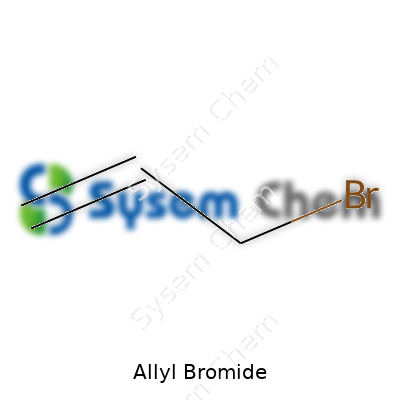

The Essentials of Allyl Bromide

Allyl bromide stands out as a simple but powerful chemical building block. Its molecular formula is C3H5Br. This formula alone reveals three carbon atoms, five hydrogens, and one bromine atom. Though compact, this arrangement drives a big chunk of innovation in labs—mostly due to its unique structural features.

Structure Makes the Difference

If you sketch the molecule, allyl bromide falls under the category of organic molecules known as alkyl halides. The structure starts with a chain of three carbon atoms. The first two carbons link with a double bond—giving an alkene “feel” to part of the molecule. The third carbon sticks out at the end and holds the bromine atom. The chemical notation for it: CH2=CH–CH2Br. In practice, chemists see it as a reactive site—prime for adding new things where the bromine sits.

The double bond makes this molecule act differently from something like propyl bromide, which lacks that reactive stretch of unsaturation. So, allyl bromide’s structure brings together two hotspots—a double bond and a reactive bromine—fueling its popularity in organic synthesis. I remember my first real brush with this molecule in college. Mixing it into a reaction, you could almost feel the anticipation: the double bond pushes for action, and the bromine gets swapped out in no time.

Why Allyl Bromide Gets Noticed in Chemistry Labs

Allyl bromide shows up on chemical shelves for good reason. In research, it acts as an alkylating agent, meaning it attaches its three-carbon “tail” to other compounds. This sort of transformation is a routine step for medicinal chemists trying out new drug structures, agrochemical researchers looking for fresh ideas, and polymer labs chasing new plastics.

Take the area of pharmaceuticals. To create a medicine that binds well to its target, a chemist might need to fine-tune the side chain on a molecule—allyl bromide makes this change smooth. The bromine acts as a “leaving group”: when you use it with a strong nucleophile, the new group kicks out the bromine atom and grabs that spot on the three-carbon chain. This method has opened the door for all kinds of creative chemistry—important for cancer drugs, anti-infectives, and pesticides. I’ve spoken with med chemists who grin at the mention of allyl bromide; its simplicity lets their innovations shine without fuss.

Working Safely With Allyl Bromide

It pays to remember that allyl bromide isn’t all sunshine for everyone who handles it. It releases vapors with a strong, almost sharp odor, and the material can irritate skin, eyes, and the respiratory tract. Heating or careless handling raises the danger level. The EPA and OSHA keep a close eye on allyl bromide due to these potential hazards. Looking out for your own safety comes first—fume hoods, gloves, and goggles all matter here. Regular training on proper handling keeps accidents away and lets innovation thrive rather than create problems.

Rethinking Chemistry With Smarter Choices

While allyl bromide has anchored many breakthroughs, the chemical world keeps evolving. Efforts now run deep to discover alternatives that match this molecule’s handy chemistry but leave behind its health and environmental risks. Green chemistry projects draw on years of experience seeing both the good and the risks, focusing on reactions that work under milder conditions or use less hazardous agents. Some labs turn to enzymatic chemistry or catalysis, letting nature or clever metals guide the reactivity instead of relying on strong alkylating agents every time.

The Realities of Handling Reactive Chemicals

Anyone who has worked in a chemistry lab knows allyl bromide is more than just another reagent on the shelf. I’ve seen firsthand why careful storage isn’t just a rule for the safety manual. The stakes are high because allyl bromide reacts readily and can ruin a day in seconds if handled wrong. I remember walking into a lab where a faint, sharp smell in the air meant someone got careless. That’s a wake-up call nobody forgets quickly—eye irritation, headache, and even worse with longer exposure. It sticks in your mind how important it is to treat this liquid with the respect it demands.

Keeping Exposure Low and Reactions Minimal

Allyl bromide boils at about room temperature; it forms vapors that can build up in any closed space. Inhaling those vapors poses health risks, from coughing to more serious respiratory harm. It’s also highly flammable, which only adds to the concern. Leaks, spills, or even a loose cap make a difference that can endanger people around. I’ve seen a vapors alarm go off once—it’s jarring and leaves you double-checking your next batch of inventory twice.

Best Practices Backed by Safety Data

Storing allyl bromide wisely means finding a cool, dry space, away from open flames and direct sunlight. A flammable storage cabinet keeps both the fire risk and its vapor in check. Not every lab invests in one right away, but after handling enough volatile chemicals, you start pushing for those upgrades. Stainless steel containers with a tight seal prevent accidental leaks and reactions with oxygen or moisture. I’ve learned to skip plastic or rusty old caps. This chemical eats through weak spots faster than people like to believe. Keeping it below 20°C slows down evaporation, making accidental release less likely.

Labeling can seem basic, but a clear, unmissable label saves confusion and cuts down on mistakes during busy days. Everyone remembers a story of staff grabbing the wrong bottle only to realize too late what they’ve opened. Keeping good records and a chemical log means no one gets surprised by an old, forgotten container lurking in storage.

Solutions Make a Real Difference

The solution sits in clear procedures and a culture of care. Good ventilation in the storage room stops vapor buildup. Installing a chemical fume hood near where containers are opened makes daily work far safer for everyone. Spill containment trays catch drips and leaks that otherwise end up on the floor or, worse, in the drainage system. Regular safety training keeps people up to speed and builds habits that become second nature. Newer staff can learn from the mistakes of those who have come before. Nothing beats practical, experience-based advice when it comes to avoiding disaster.

Staying prepared for emergencies rounds off smart storage. That means eyewash stations close to storage, proper fire extinguishers, and a spill kit that’s always stocked and ready. It makes the whole process smoother and gives everyone in the lab more confidence handling tricky situations. Each layer of precaution not only protects health and equipment but shows respect for the work and the people doing it.

Understanding the Risks of Allyl Bromide

Allyl bromide crops up in a lot of chemical labs. It acts as a building block for countless products, from pharmaceuticals to pesticides. Despite its usefulness, I can’t help but notice deep concerns about its safety. Many chemists, especially those who hang around universities or small labs, know that feeling of cracking open a bottle and immediately smelling that strong, stinging odor. That sharp scent always sets nerves on edge, not just because it's irritating, but because it’s a warning sign—this compound doesn’t play around.

Taking Stock of Health Hazards

People rarely forget the first time they get a whiff of allyl bromide. Eyes burn, nose runs, and coughing hits hard. Common sense tells anyone this chemical can do damage even in small amounts. Factually, allyl bromide acts as a serious irritant for the skin, eyes, and lungs. Strong fumes can trigger severe respiratory distress—symptoms often get worse with repeated exposure. Scientists rank it as a potential human carcinogen. Studies show it can harm your central nervous system, cause headaches, and even tricky symptoms like confusion or sleepiness if you inhale enough. The liquid itself can blister the skin on contact. Sometimes, safety goggles or gloves rip after a quick spill, costing folks a trip to urgent care.

Why Environmental Risks Don’t Disappear

Allyl bromide doesn’t stay just in the flask. Many of us have seen colleagues rush to dilute spills or uses fume hoods at full blast. Its vapor creeps into the air fast and can hang around if ventilation isn’t up to scratch. Wind or rain doesn’t break it down quickly outside, so this isn’t just a problem for lab techs. Leaks or improper waste means contamination can get into soil and water. Ecosystems don’t handle allyl bromide well; this stuff poisons fish and small critters fast. Communities with chemical plants or persistent leaks face real risks—children playing near old drum sites or gardens don’t always get fair warning.

What Recall and Regulation Teach Us

Allyl bromide sits on lots of regulatory watch lists. Agencies like OSHA in the United States or the European Union’s ECHA classify it as a hazardous substance. Workers require strict exposure monitoring. Labels and restricted use laws send a clear message: the dangers are real, documented, and recognized. In the late 1970s, one chemical plant accident in New Jersey led to tighter state-wide rules after workers fell ill and local streams got contaminated. Even years later, regulators track sites closely to make sure spills stay contained.

Protecting People and the Planet

Anyone familiar with organic chemistry feels the pressure to work cleaner, smarter, and safer. Ventilation systems get regular upgrades; spill kits get checked often. Labs ditch glass ampules for safer packaging. Training makes a difference—teaching new students to recognize symptoms and secure containers pays off. Smart disposal closes the loop. Collecting allyl bromide waste for professional incineration keeps it away from water sources.

Switching to less harmful substitutes remains a work in progress, but companies and researchers push for greener pathways every year. While nobody expects allyl bromide to leave the scene tomorrow, taking every possible step to keep it contained reflects how much care matters—both for human health and the world we all share.